Material Balance Fly Jaw Crusher

.jpg)

(PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

2017年6月30日 — This study reports on the design optimisation of the swinging jaw crusher plate Jaw crusher machines are used in the mining and construction industry for 2022年12月31日 — By changing the eccentric counterweight and counterweight angle of the crusher flywheel, the centroid of the eccentric shaft, flywheel, and large pulley can meet Balance Optimization of Inertia Force of Jaw Crusher2024年8月20日 — The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between Jaw Crusher Basics in 3 MinutesSBM Industrial Technology 2022年11月21日 — Crushing jaws made of highgrade austenitic manganese steel, cheek plates made of highstrength special steel Crushing jaws can freely expand, avoiding Industrial Solutions Jaw crushers ThyssenKrupp

Jaw Crusher SpringerLink

The material entering the crushing cavity is crushed by the combined action of squeezing, splitting, and bending, and the crushed material is discharged from the discharge port 2024年9月24日 — The inertia required to crush the material is provided by a weighted flywheel that moves a shaft creating an eccentric motion that causes the closing of the A REVIEW ON STUDY OF JAW CRUSHER 911 Metallurgist2014年4月15日 — Two optimal energy control strategies of a jaw crushing process are modelled • Potential of energy cost saving and energy saving is demonstrated • More Optimal energy management for a jaw crushing process in 2022年11月24日 — A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model Dynamics Analysis and Chaos Identification of

.jpg)

Influence of jaw crusher parameters on the quality of

2020年6月1日 — A parameter study using a jaw crusher is designed to investigate the influence of feed gradation, feed rate, crusher setting and crusher speed on the crusher 2023年2月15日 As one of the most commonly used jaw crusher, blake jaw crusher has two types: Single toggle jaw crusher An eccentric shaft is positioned on the top of the crusher The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding Material Balance Fly Jaw Crusher technesrl2021年4月7日 — JAW CRUSHER QJ341+ JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C12 jaw crusher Feed opening 120 m x 750 mm / 47” x 29” Maximum feed size 650 mm³ / 256 inch³ Engine CAT C93B Stage 5 / T4F 280 kW / 375 hp CAT C9 T3 261 kW / 350 hp Transport dimensions 1472 m / 48’ 3” (l) 279 m / 9’ 2” (w) TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW 2017年6月30日 — A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

.jpg)

“Computer Aided Design of Jaw crusher” 911 Metallurgist

2024年7月30日 — Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" 2024年3月15日 — Dalam artikel ini, kita akan membahas pengertian, prinsip kerja, komponen utama, serta peran dan kegunaan mesin jaw crusher dalam pengolahan material Pengertian Mesin Jaw Crusher Mesin jaw crusher adalah mesin pemecah batu yang digunakan untuk mengurangi ukuran material menjadi bagian yang lebih kecilMemahami Mesin Jaw Crusher: Peran dan Kegunaannya 2003年5月7日 — Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined TECHNICAL NOTES 5 CRUSHERS Mineral Tech2018年1月17日 — group, has installed over 10 000 jaw crushers since the 1920s Today the Nordberg C Series is indisputably the world’s favourite jaw crusher Where costefficient primary reduction of hard, abrasive materials is concerned, C Series crushers represent the highest technical and manufacturing knowledge All C Series jaw crushers are based on aNordberg C Series jaw crushers International Crusher

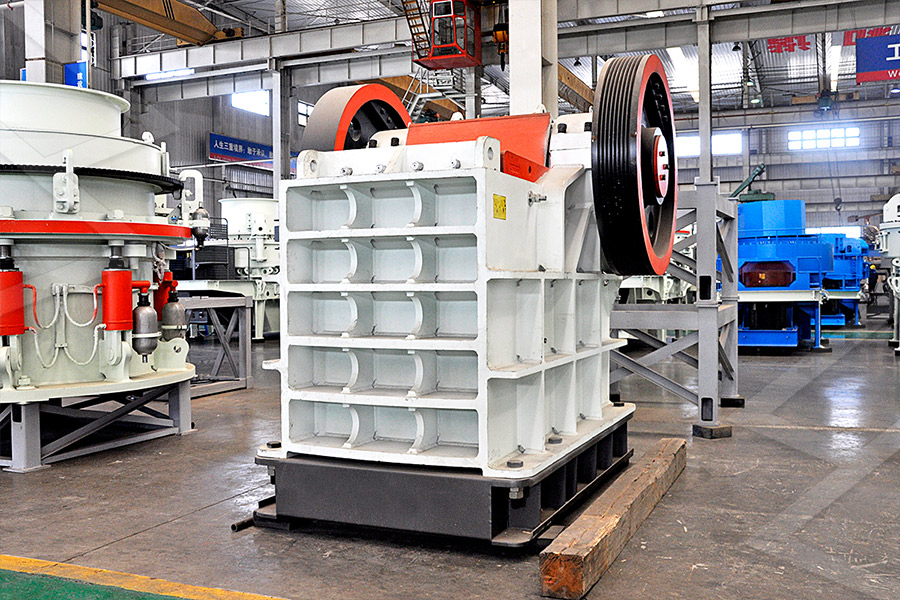

Jaw Crusher For Sale Jaw Crusher Jaw Crusher Manufacturer

The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa Widely apply for mining, cement and concrete industries It is mainly used as coarse crusher and medium crusher in mines, building materials and infrastructureThe main task of the fixed jaw of the jaw crusher is to hold the material to be crushed in place so that it does not slip when the force is applied The movable jaw exhibits a periodic to and fro motion and generates the necessary force to break down the object into small pieces The angle between the moveable and the fixed jaw is roughly set Jaw Crusher Working Principle StudiousGuy2022年11月21日 — Solutions has in its range two types of jaw crusher, which differ in the kinematics of hardrock version of the singletoggle jaw crusher are based on hard feed material that is difficult to crush 90 120 150 200 230 270 300 1 10 100 1,000 Mesh size [mm] 100 90 80 70 60 50 40 30 20 10 0 CSS jaw opening [mm] Passage [wt%]Industrial Solutions Jaw crushers ThyssenKrupp2021年2月1日 — Crusher product is dependant on feed material properties Please consult Terex MPS for advice on product gradations for specific feed materials Versatility for Jaw Crusher, 52” x 20’ Feeder 200 hp (150 kW) 255 – 760 (231 690) (6) 40ft shipping containers plus (1) flat rack Model Main Components Motor Size Capacity (MTPH)Jaw Crushers JW Series Terex

.jpg)

Jaw crusher EB FLSmidth

Consistent crushing at high throughputs – our Jaw Crusher EB is the solution for crushing mediumhard to very hard materials Thanks to the optimised crusher speed and generously dimensioned fly wheels our 2023年11月14日 — without any restrictions When the articulated crusher jaw is pulled up, the material cannot pile up and fewer blockages are created The deflector plate at the crusher outlet guarantees gentle material transfer onto the crusher discharge conveyor The large material tunnel prevents blockades and is easily accessible from the sideMobile jaw crusher MOBICAT MC 100(i) EVO2021年5月6日 — The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw The crusher discharge opening governs the size of finished material produced by the crusher Measuring Discharge Opening: Measure distance at bottom of jaws at the point of the crushing cycle Jaw Crusher Working Principle 911Metallurgist2023年2月21日 — Before selecting a jaw crusher, there are several factors that you should consider to ensure that the machine meets your specific needs Some of the key factors include: Capacity: The amount of material that a jaw crusher can process per unit time is a critical consideration Ensure that the jaw crusher you select can handle the amount of The Ultimate Guide to Jaw Crushing Machines: Types

Universal Jaw Crushers McLanahan

Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first overhead eccentric jaw crushers Since that time, this robust design has continued to be the basis of the Universal Jaw Crusher design In addition to the standard jaw crusher design, McLanahan also produces the HSeries, which features adjustonthefly capabilities1 天前 — A small jaw crusher is a type of jaw crusher that is specifically designed for smallscale operations, laboratories, or where space and capacity constraints exist These crushers are suitable for crushing small amounts of hard materials into smaller, more manageable pieces Laboratories: For sample preparation and testingSmall Jaw Crusher TAYMACHINERYlimestone using a crusher crusher, this activity uses 3 crusher units with a production target of each crusher A 25 tons/hour, crusher B 25 tons/hour, and crusher C 5 tons/hour so that the total production is 1750 tons/month In October PT Sumbar CalciumAnalisis Kinerja Crusher Pada Kegiatan Produksi Batu 2024年9月6日 — JW Series Jaw Crusher Enquiry Details 15 When enquiring about the range of Terex® JW Series Jaw Crushers please supply the following details so that the jaw crusher best suited may be recommended ( or fax this form to your local Terex® Minerals Processing Systems office) Type of material to be crushed Bulk density of feed Terex Minerals Processing Systems JW SERIES JAW

.jpg)

Nordberg® C Series™ jaw crushers Metso

A larger feed opening increases material intake and ensures that the rocks enter the jaw crusher’s cavity without restrictions A steeper nip angle decreases operating costs by reducing wear on jaw dies and speeds up material flow down in the cavity The stroke is amplified from top to bottom, leading it being longest in the bottom of the cavity2024年9月26日 — How To Use A Jaw Crusher? If you want to use a jaw crusher to crush rocks or other materials, there are a few key things that you should keep in mind First, you will need to carefully select the jaw plates Jaw Crusher: What Is It How Does It Work?2023年12月30日 — Jaw crushers are utilized to crush raw materials in the ceramics and glass industries, facilitating the production of finely ground materials for manufacturing processes Buildmate: Pioneering Introduction to Jaw Crushers: Understanding the 2023年2月15日 — Additionally, the double toggle jaw crusher is more expensive than other types of jaw crushers Blake jaw crusher The Blake jaw crusher was first introduced in 1858 by Eli Whitney Blake This type A Guide to Types of Jaw Crushers for Crushing

Understanding Types of Jaw Crusher: A Comprehensive

The mobility of these crushers reduces the need for transporting material to the crusher, thus lowering operational costs Mobile jaw crushers are equipped with direct drive systems and advanced control technologies, optimizing performance for various applications, from demolition and recycling to mining and quarryingFor example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top ie the opening), and each jaw will have a 54inch width If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimensionJaw Crusher Explained saVRee2016年1月16日 — The Blake crusher in common with all machines of the jaw family is built into a rectangular frame, at one end of which is located the crushing chamber; in fact, the end of the boxframe constitutes the stationary jaw The movable or swing jaw is suspended from a crossshaft (swing jaw shaft) at its upper end, this shaft in turn being supported Blake Jaw Crusher 911Metallurgist2021年4月8日 — Dibandingkan dengan mesin crusher lainnya, jenis jaw crusher lah yang paling sederhana sistem operasionalnya Mesin ini berfungsi sebagai penghancur material yang menghasilkan material lebih kecil Jaw crusher masuk dalam kategori crusher primer, karena menghasilkan ukuran material yang lebih kecil Mengenal Mesin Penghancur Batu Tipe Jaw Crusher yang

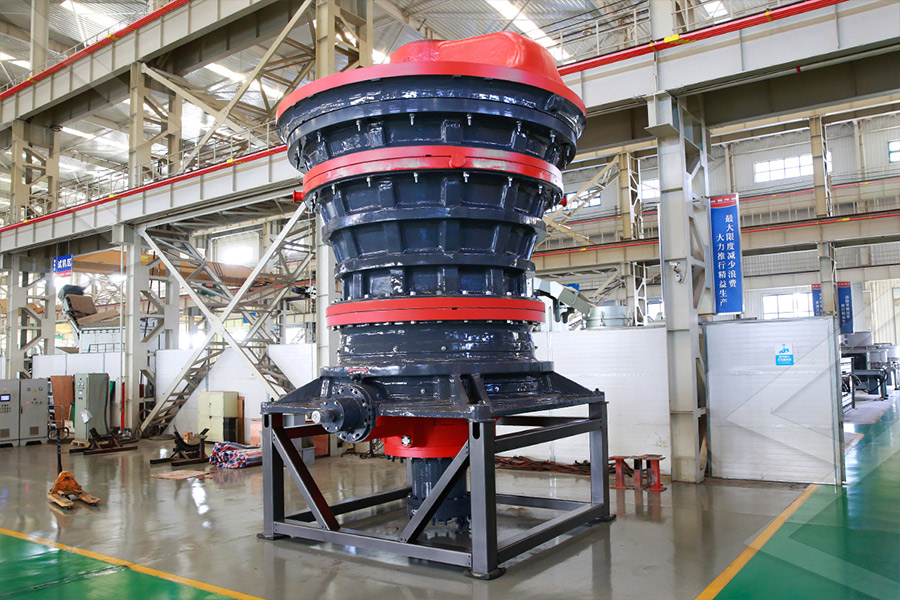

Understanding the Cone Crusher Working Principle For Right

2023年2月21日 — If you're in the market for a cone crusher, it's important to understand the machine's working principle to make an informed decision In this comprehensive guide, we'll explain the working principle of a cone crusher, its components, maintenance tips, benefits, and offer practical advice on how to choose the right cone crusher for your application2024年4月19日 — Jaw Crusher: Uses a reciprocating jaw to compress and crush material against a stationary plate: Primary crushing stage, handles large, abrasive materials: Up to 1,500 mm: 50300 mm: Moderate to high: Simple design, reliable, handles abrasive materials: Limited reduction ratio, lower capacity compared to gyratory crushers: Cone Types of Crushers Explained: Everything You Need to Know2020年3月19日 — Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but there are application drawbacks that may make another crushing solution more appealing First, cone crushers cannot accept all material sizes Any material fed to the crusher must be presized for that particular crusher (usually 200mm or less)Selecting the right crusher for your operations QuarryAs a rule, Jaw Crushers have a 6:1 or 8:1 ratio for crushing material Still using the 32 x 54 Jaw Crusher example, the top size of the feed entering the crushing chamber has to follow the F80 rule that 80% of the top size feed Jaw Crushers McLanahan

.jpg)

ESCO Weir Group

2022年12月1日 — • Excellent for jaw crusher liners, conecrusher bowl liners and mantles Alloy 14HN / 14L: chrome bearing manganese • Less susceptible to cold flow • Parts of lighttoheavy section thickness for heavyduty applications • Used in large gyratory crusher mantles, concaves, cone and jaw crusher parts – as well as in impact2023年2月28日 — Maximizing crusher performance and productivity requires selecting the right jaw crusher size and capacity Learn how to determine the optimal size and capacity for your application, and discover the benefits Choosing the Right Jaw Crusher Size and 2020年4月1日 — The Sandvik jaw crusher above is designed for the motor sizes listed in RPG and technical specifications This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor Using oversized motors will lead to radically shorter crusher life and various mechanical problemsSANDVIK JAW CRUSHER SERIES Sandvik Mining and Jaw crushers are largescale, heavyduty machinery typically constructed with cast iron and/or steel Often considered a basic machine, jaw crushers have their place in the industry They are often used to reduce rock into nonuniformed gravel To find out more about primary jaw crusher check out our blog Cross section of a Kleeman primary jaw Types of Crushers: What You Need to Know HUATAO GROUP

Crusher Spare Parts Qiming Casting

4 天之前 — Spare Parts For Different Crushers Jaw Crusher Replacement Spare PartsEccentric Shaft, Balance Plate, Fly Wheel, Crusher Frame, Fixed Jaw Plate Shim, Retraction Spring, Groove Block and so on; Impact Crusher Replacement Spare PartsRotor, Discharge Opening, Hydraulically Operated Crusher Service Door, Impact 2023年2月21日 — Cone crushers are commonly used in the mining and aggregates industries to reduce the size of raw materials, such as rocks and minerals These machines are powerful, efficient, and versatile, but they rely on highquality wear parts to function effectively In particular, the cone crusher liners, also known as concave and mantle Ultimate Guide to Cone Crusher Liners: Materials, Designs2023年2月28日 — The jaw crusher works by moving the material between a fixed and a moving plate The moving plate applies force to the material, causing it to break down into smaller pieces The gyratory crusher, on the other hand, uses a mantle and concave surfaces to compress the material The mantle is located above the concave, and as the Primary Crusher vs Secondary Crusher: Understanding Their The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw crusher takes Jaw Crusher SpringerLink

.jpg)

High Quality Jaw Crusher Spare Parts Fly Wheel Grey Iron

2024年9月20日 — High Quality Jaw Crusher Spare Parts Fly Wheel Grey Iron Sand Casting, Find Details and Price about Crusher Machine Pulley Wheels from High Quality Jaw Crusher Spare Parts Fly Wheel Grey Iron Sand Casting Beijing Rubble Technology Co, Ltd Features of cone crusher wear parts : 1) Material: high manganese steel:Mn13Cr2, 2023年2月15日 As one of the most commonly used jaw crusher, blake jaw crusher has two types: Single toggle jaw crusher An eccentric shaft is positioned on the top of the crusher The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding Material Balance Fly Jaw Crusher technesrl2021年4月7日 — JAW CRUSHER QJ341+ JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C12 jaw crusher Feed opening 120 m x 750 mm / 47” x 29” Maximum feed size 650 mm³ / 256 inch³ Engine CAT C93B Stage 5 / T4F 280 kW / 375 hp CAT C9 T3 261 kW / 350 hp Transport dimensions 1472 m / 48’ 3” (l) 279 m / 9’ 2” (w) TECHNICAL SPECIFICATIONS SANDVIK QJ341+ JAW 2017年6月30日 — A review on the design and operations challenges of a single toggle jaw crusher is presented Strength and fracture toughness of the material to be crushed are intrinsic properties that determine (PDF) DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER

.jpg)

“Computer Aided Design of Jaw crusher” 911 Metallurgist

2024年7月30日 — Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" 2024年3月15日 — Dalam artikel ini, kita akan membahas pengertian, prinsip kerja, komponen utama, serta peran dan kegunaan mesin jaw crusher dalam pengolahan material Pengertian Mesin Jaw Crusher Mesin jaw crusher adalah mesin pemecah batu yang digunakan untuk mengurangi ukuran material menjadi bagian yang lebih kecilMemahami Mesin Jaw Crusher: Peran dan Kegunaannya 2003年5月7日 — Figure 51 Schematic diagram of a crusher showingg the open and closedside settings 51 Jaw and Gyratory Crushers Jaw and gyratory crushers are used mostly for primary crushing They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material The capacity of the crusher is determined TECHNICAL NOTES 5 CRUSHERS Mineral Tech2018年1月17日 — group, has installed over 10 000 jaw crushers since the 1920s Today the Nordberg C Series is indisputably the world’s favourite jaw crusher Where costefficient primary reduction of hard, abrasive materials is concerned, C Series crushers represent the highest technical and manufacturing knowledge All C Series jaw crushers are based on aNordberg C Series jaw crushers International Crusher

.jpg)

Jaw Crusher For Sale Jaw Crusher Jaw Crusher Manufacturer

The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa Widely apply for mining, cement and concrete industries It is mainly used as coarse crusher and medium crusher in mines, building materials and infrastructureThe main task of the fixed jaw of the jaw crusher is to hold the material to be crushed in place so that it does not slip when the force is applied The movable jaw exhibits a periodic to and fro motion and generates the necessary force to break down the object into small pieces The angle between the moveable and the fixed jaw is roughly set Jaw Crusher Working Principle StudiousGuy2022年11月21日 — Solutions has in its range two types of jaw crusher, which differ in the kinematics of hardrock version of the singletoggle jaw crusher are based on hard feed material that is difficult to crush 90 120 150 200 230 270 300 1 10 100 1,000 Mesh size [mm] 100 90 80 70 60 50 40 30 20 10 0 CSS jaw opening [mm] Passage [wt%]Industrial Solutions Jaw crushers ThyssenKrupp