Iron Mining Process Plant

Iron Ore Processing: From Extraction to Manufacturing Mining

2024年4月26日 — Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in producing highquality iron ore productsIron Processing Solution Here we will give a breif introduction to typical mineral Iron Processing SolutionIron processing, use of a smelting process to turn the ore into a form from which products can be fashioned Included in this article also is a discussion of the mining of iron and of its preparation for smeltingIron processing Definition, History, Steps, Uses, 2022年1月1日 — In many instances, China’s iron ore beneficiation plants are designed to recover more than just the iron minerals from the ore For example, the processing plants Introduction: Overview of the global iron ore industry

.jpg)

The six main steps of iron ore processing Multotec

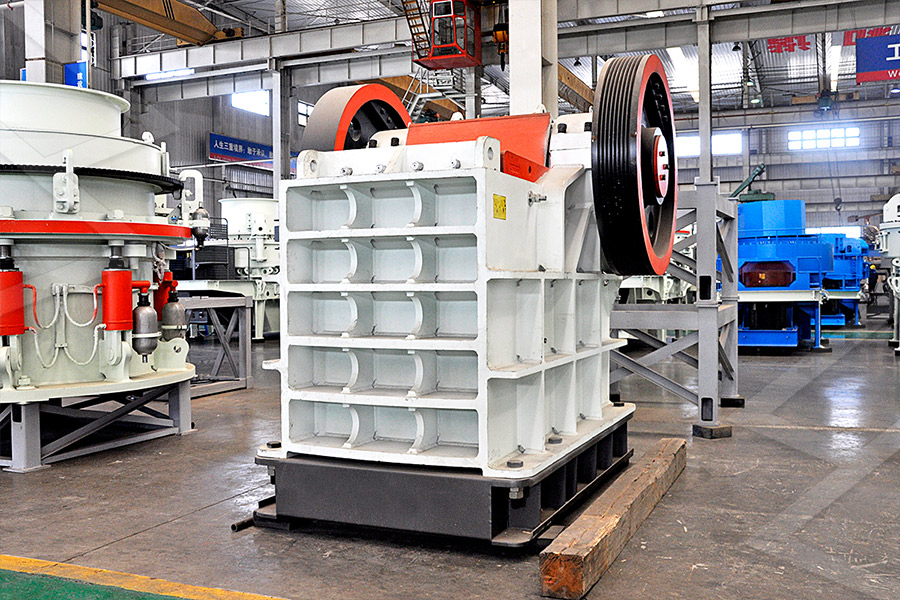

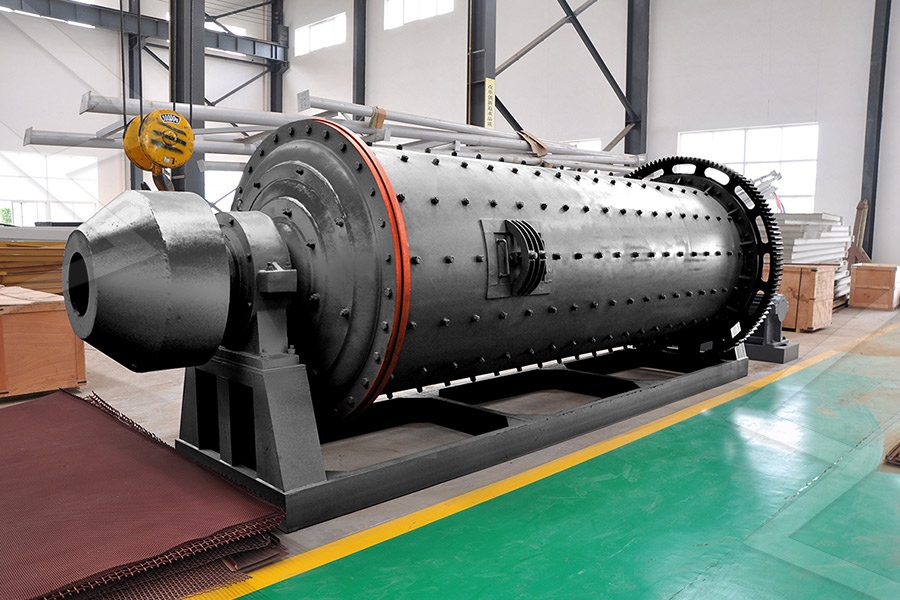

Learn about the steps involved in iron ore processing, from crushing and grinding to separation Contact Multotec experts for guidance on iron processing2023年9月20日 — Figure 2 presents CO 2 emissions and crude steel output of all iron and steel plants operating in 2019 by regions (see Extended Data Fig 3 for a detailed Global iron and steel plant CO2 emissions and carbon 2022年10月20日 — Making iron and steel from iron ore requires a long process of mining, crushing, separating, concentrating, mixing, agglomeration (sintering and pelletizing), Iron Ore Processing, General SpringerLink2019年8月23日 — Iron processing description from its geology mineral property to how to extract mineral from rock and placer deposit, related processing plant flow chart and layout designIron Processing Equipment, Process Flow, Cases

.jpg)

Iron Processing Solution Miningpedia

Iron Processing Solution Here we will give a breif introduction to typical mineral processing solutions we have carried out before Each case will be explained with ore property, Recent advancements in process mineralogy have furthered the cause of integrating mine site geology and process plant to a great extent with a main focus on improving the value of the mine Geometallurgy relates to the Physical Processing: Innovations in Mineral 2020年7月26日 — ABSTRACT The recent progress and development of ironmaking in China as of 2019 was introduced China has achieved a remarkable progress in eliminating outdated production capacity of steel Recent progress and development of With its completion, Northshore Mining is the first USbased iron ore processing facility to produce low silica DRgrade pellets The Northshore operation is producing DRgrade pellet feedstock inventory for Cleveland Iron Ore Facilities :: ClevelandCliffs Inc (CLF)

.jpg)

Iron Bridge Magnetite Project, Australia Mining

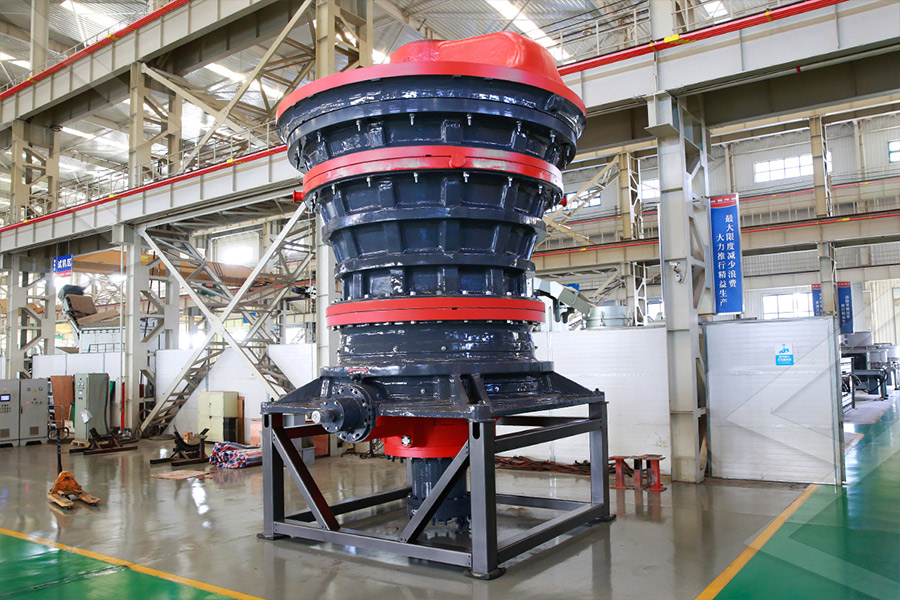

2020年11月2日 — Mining at Iron Bridge project The processing plant will use dry crushing and grinding circuit The plant will employ the KB 63130 type gyratory crushers, which will be the largest crushers in the country Our mines and processing plants are located in Kiruna, Malmberget and Svappavaara The mines are the heart of our business; everything starts in the mine The road from mine to steel is a long journey that begins with From mine to port LKAB2023年12月15日 — The company is entitled to royalties from BHP Billiton’s iron ore mining in Western Australia Besides Australia, the company’s enterprises are in North America and Sri Lanka “Rio Tinto” is the world’s secondlargest mining company, operating in 20 countries and extracting iron ore, copper, coal, uranium, aluminum, diamonds, and goldTitanium Ore Plant: Efficient Mining and Processing Methods2023年6月2日 — Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the processIron Ore production in the Pilbara Rio Tinto

.jpg)

Iron Ore Beneficiation Plant Equipment For Mining Process

2023年9月4日 — Jig machine: processing 30 (2)~05mm coarse iron ore; Shaking table: separating 2~0037mm fine iron ore particles; Spiral chute: processing 01037mm iron ore with low mud content 4 Iron ore dewatering equipment The iron ore mine dewatering operation divides into two parts: concentrate mine dewatering and tailings mine Our operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in SeptIles","3821":"The Iron Ore Company of Canada is owned Compagnie minière IOC ironoreca2024年5月9日 — The ore needs to be brought to the plant in an efficient way to enable the iron ore mining process to be carried out effectively Step 4: Crushing and Grinding – Ore Preparation for Separation At the plant, machines called crushers smash the Iron Ore Mining Essentials: Key to Steel Production JXSCThe Iron Ore Company of Canada (IOC) is a leading Canadian producer of iron ore concentrate and iron ore pellets that serves customers worldwide operations are integrated across a mine and processing plant in Labrador City, Newfoundland and Labrador; a port and stockpile in SeptIles, Quebec; and a 418 kilometre railway that Iron Ore Company of Canada Rio Tinto

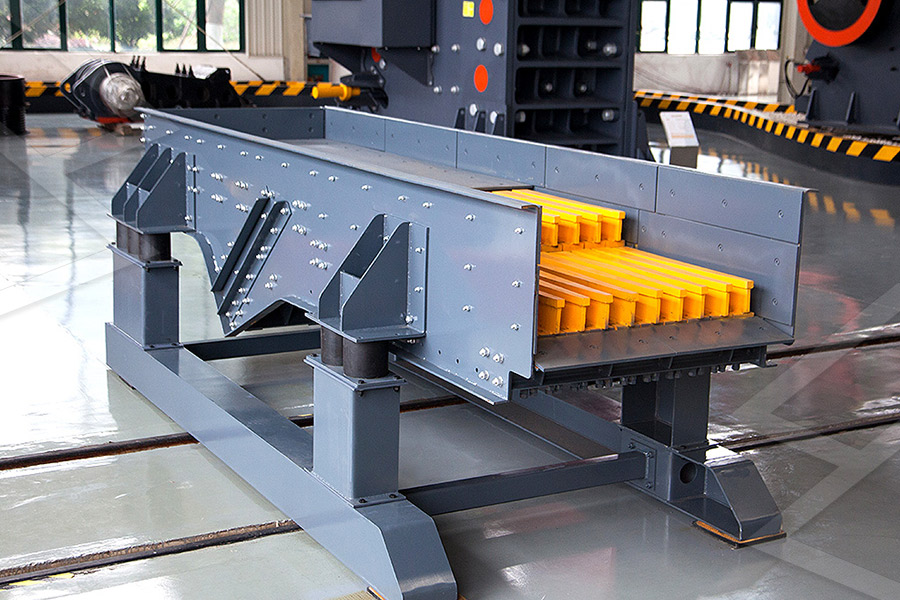

The process Kaunis Iron

Kaunis Iron’s openpit mine in Pajala is just the starting point of the ore’s journey to customers around the world Here you can read about the process to refine the muchwanted iron ore In the screening plant, the larger pieces are separated from the finer fragments before being transported to the stockpile where they are stored Essel Mining and Industries Limited (EMIL) is a pioneer in manufacturing of iron pellets through the distinguished and most compact circular Pelletization Technology (CPT) BENEFICIATION PLANT: The beneficiation Iron Ore – Beneficiation Pelletization DivisionIron Duke and Iron Baron, Arrium, Australia; Bhushan Power and Steel, India; Roy Hill Iron Ore, Australia; Christmas Creek, FMG, Australia; With teams located in major mining regions around the world, we can work Iron ore beneficiation Commodities Mineral 02 China 3500TPD Iron Mining and Processing Plant Ore Properties The metallic minerals were magnetite, hematite, limonite; the nonmetallic mineral was quartz Only Fe in the raw ores has recycling value, and the raw ores belong to original acid magnetite with low phosphorus and low sulphurIron Processing Solution Miningpedia

Iron Ore Processing, General SpringerLink

2022年10月20日 — There is a long and rich history of iron ore mining and processing Prior to the industrial revolution, most iron was obtained from widely available goethite or bog ore Prehistoric societies used laterite as a source of iron ore One of the successful applications of anionic flotation process was the iron ore flotation plant at Marquette 3 天之前 — This is a complete 500tph iron ore crushing plant layout, raw ore information and process details are as follows: Rock iron ore, magnetite Fe3O4; Rock ore needs to be crushed to less than 5mm to be released into the iron interior; dry process requiredIron Ore Beneficiation Plant JXSC Machinery2024年3月26日 — Sino Iron is the largest magnetite mining and processing operation in Australia – 100km south west of Karratha in Western Australia’s resourcerich Pilbara region We use traditional open pit mining techniques to excavate the ore, then put it through a rigorous beneficiation process right here on site, producing a high grade, premium Our Operation Citic Pacific Mining2023年11月26日 — The chrome plant process flow begins with exploration and mine development Geologists conduct surveys and studies to identify potential chrome ore deposits Once a suitable site is identified, the mining process commences This involves clearing the land, creating access roads, and establishing infrastructure to support mining StepbyStep Guide: Chrome Plant Process Flow Explained Mining

extraction of iron, process of iron, iron processing, iron mining

Philippines iron mine processing plant is a large and one of successful cases of Xinhai The Purposes of Iron Mine Processing Plant: 1 improving the iron ore grade for smelting or selling directly 2 removing unqualified particle size for smelting process Come up with your requirement, xinhai will give you the completed flow like this video 2021年12月23日 — LKAB upgraded its ore processing capability a few years by adding an RMD system as part of a continuous program of expansion in an area that has been home to iron ore mining since the mid18 th RANKED: World’s top 20 biggest iron ore operations MINING2021年7月29日 — The wet processing plant is a significant part of the new magnetite mine at Iron Bridge, which will be central to the production of 22 Mt/y (wet) of 67% Fe magnetite concentrate product SIMPEC is to SIMPEC to construct wet process plant at Iron2014年10月1日 — Using computer models for process design is a wellestablished practice in the mineral industry In recent years, there has been emphasis on modeling of processing plant as a wholeModeling and simulation for design of iron ore processing plant

.jpg)

Samarco Iron Ore Mine, Alegria, Brazil Mining

The process plant pumps concentrate via a slurry pipeline to facilities at Ponta Ubu on the Atlantic coast that include two pelletising plants and a shipping quay BHP Billiton and CVRD (Vale) each has a 50% holding in Significant innovations include a digital replica of the processing plant that’s accessible in real time by workers in the field; integrated mine automation and simulation systems Innovations at GudaiDarri include autonomous water carts, a rotable bucket wheel reclaimer, and a fully automated laboratory integrated within the mineIron Ore Western Australia Rio Tinto2023年8月29日 — processing plants that reduce risk, shorten project implementation and maximise returns in difficult project locations SGS Bateman modular plants are self contained or are integrated into conventional plants They are used for prospecting, exploration, research, pilot plant and mineral processing on land or sea The processModular Plants: Gold Processing2017年7月10日 — The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking Iron Ore Pelletizing Process: An Overview IntechOpen

Iron Ore Supply Chain: From Mining to Steel Production

2023年10月25日 — Iron ore is a crucial raw material for the global steel industry, and its supply chain is a complex network that involves multiple stakeholders and activities The iron ore supply chain begins with the mining of iron ore, which is then transported to processing plants for beneficiation and further refinement The refined iron ore is then transported to The process of iron ore mining and mineral processing involves several steps, including:Exploration and discovery: This is the process of finding iron ore deposits Geologists use a variety of methods to explore for iron ore, including mapping, sampling, and geophysical surveysMining: This is the process of extracting iron ore from the prehensive Guide to Iron Ore Mining and Mineral Processing2018年7月20日 — The article describes features of ore reserves and development of processing technologies at Mikhailovsky MPP New approaches to disintegration of ore and to improvement of dry magnetic separation of unoxidized ferruginous quartzite are evaluated The scope of the discussion embraces the process of finishing magnetite Innovative Solutions in Iron Ore Production at Mikhailovsky Mining and 4 天之前 — Silica Sand Mining introduces Foundry silica sand is the quartz as the main mineral composition, particle size of 0020 mm to 3350 mm refractory particles, according to the mining and processing methods of Silica Mining Processing Equipment Flow

.jpg)

Innovative Solutions in Iron Ore Production at Mikhailovsky Mining

2017年9月1日 — It may be noted that corn starch accounts for more than 70% of the global starch production and its price is about 290300 USD/MT, which is lower compared to tapioca starch ($350360/MT) and wheat The Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces Transportation The taconite pieces are scooped up by electric Mining Process Iron Mining Association taconite2018年9月18日 — Characterization and beneficiation of dry iron ore processing plant reject fines of Khondbond region, India, was investigated Different characterization techniques viz size analysis, sizewise chemical and density analysis, Xray diffraction analysis, sinkfloat analysis, thermo gravimetric analysis, scanning electron microscopy, and QEMSCAN Characterization and Beneficiation of Dry Iron Ore Processing Plant Sourcing Guide for Iron Ore Process Plant: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: mining equipment, gold mining equipment, screening machineIron Ore Process Plant MadeinChina

10 Best Ore Beneficiation Plants for Sale (with Costs)

2021年3月24日 — "This mobile gold mine processing line solved my site limitation and helped me save 66% of the cost" —— Abubakar 04 Case site 10 TPH iron ore beneficiation plant in the USA Capacity: 10 t/h: Raw material: iron ore: Estimated investment: 20000$ Iron ore grade : Low grade: Ore beneficiation method: magnetic separation: Opening size: 65mm:2024年6月14日 — The iron ore enters the plant and in the plant the iron ore is crushed, grinded, magnetic separated and gravity concentrated, etc, gradually the iron can be retrieved from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Gameplay Iron ore from the iron mine Iron ore processing plant Workers Resources: Soviet 2021年3月18日 — There are also one and two stages of grinding Generally, the first stage grinding process is suitable for small CIP gold processing plants, and the second stage grinding process is suitable for medium and large CIP gold processing plants and processing fine or unevenly embedded gold mines (Grinding and classifition process for gold ore) #4How Does A CIP Gold Processing Plant Work? Miningpedia1 天前 — Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and Copper Mining and Processing: Processing Copper Ores

Extraction of Iron, Iron Mining, Iron Ore Processing Xinhai Mining

Xinhai Mining, as a mineral processing equipment manufacturer with over20year experience, provides responsible iron ore processing technologies by different type of iron ores Magnetite Iron Ore Processing Yunnan 100t/d Iron Ore Processing Plant Processing flow: Strong magnetic separation: twoandhalfblock close circuit crushing With its completion, Northshore Mining is the first USbased iron ore processing facility to produce low silica DRgrade pellets The Northshore operation is producing DRgrade pellet feedstock inventory for Cleveland Iron Ore Facilities :: ClevelandCliffs Inc (CLF)2020年11月2日 — Mining at Iron Bridge project The processing plant will use dry crushing and grinding circuit The plant will employ the KB 63130 type gyratory crushers, which will be the largest crushers in the country Iron Bridge Magnetite Project, Australia Mining Our mines and processing plants are located in Kiruna, Malmberget and Svappavaara The mines are the heart of our business; everything starts in the mine The road from mine to steel is a long journey that begins with From mine to port LKAB

Titanium Ore Plant: Efficient Mining and Processing Methods

2023年12月15日 — The company is entitled to royalties from BHP Billiton’s iron ore mining in Western Australia Besides Australia, the company’s enterprises are in North America and Sri Lanka “Rio Tinto” is the world’s secondlargest mining company, operating in 20 countries and extracting iron ore, copper, coal, uranium, aluminum, diamonds, and gold2023年6月2日 — Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the processIron Ore production in the Pilbara Rio Tinto2023年9月4日 — Jig machine: processing 30 (2)~05mm coarse iron ore; Shaking table: separating 2~0037mm fine iron ore particles; Spiral chute: processing 01037mm iron ore with low mud content 4 Iron ore dewatering equipment The iron ore mine dewatering operation divides into two parts: concentrate mine dewatering and tailings mine Iron Ore Beneficiation Plant Equipment For Mining ProcessOur operations include a mine with five operational pits, a concentrator and a pelletizing plant located near Labrador City and the whollyowned 418 km railroad, the Quebec North Shore and Labrador Railway (QNSL), that links our Labrador operations to Companyowned port facilities in SeptIles","3821":"The Iron Ore Company of Canada is owned Compagnie minière IOC ironoreca

Iron Ore Mining Essentials: Key to Steel Production JXSC

2024年5月9日 — The ore needs to be brought to the plant in an efficient way to enable the iron ore mining process to be carried out effectively Step 4: Crushing and Grinding – Ore Preparation for Separation At the plant, machines called crushers smash the The Iron Ore Company of Canada (IOC) is a leading Canadian producer of iron ore concentrate and iron ore pellets that serves customers worldwide operations are integrated across a mine and processing plant in Labrador City, Newfoundland and Labrador; a port and stockpile in SeptIles, Quebec; and a 418 kilometre railway that Iron Ore Company of Canada Rio TintoKaunis Iron’s openpit mine in Pajala is just the starting point of the ore’s journey to customers around the world Here you can read about the process to refine the muchwanted iron ore In the screening plant, the larger pieces are separated from the finer fragments before being transported to the stockpile where they are stored The process Kaunis Iron