Grinding Center For Roller Mills

.jpg)

Roller Mill Springer

2023年7月4日 — Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) 2009年1月1日 — This example shows that grinding circuit simulation can be used to analyze the production circuit, to optimize the operating parameters and to reduce energy Grinding process within vertical roller mills: experiment and 2017年7月29日 — Roller mill for cement raw material grinding in China The extensive range of Polysius roller mills provides requirementspecific solutions for the economic, reliable Polysius Roller Mills For grindingRaymond®辊磨 Raymond ® 辊磨是一种风扫式立式环辊磨机,具有集成的选粉系统,可同时干燥、粉磨和分选石灰石、粘土、矿物等多种不同类型的产品。 这款辊磨采用尺寸 Raymond®辊磨——风扫式立式环辊磨机

PROCESS OPTIMISATION FOR LOESCHE GRINDING

2017年8月12日 — For over 100 years the company Loesche has been building vertical roller grinding mills for grinding: Coal Cement raw material Clinker / granulated slag Industrial Bühler roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functionsRoller Mills Milling Bühler Group1 天前 — The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy SikaGrind® for vertical roller mills2017年8月12日 — Loesche roller grinding mills, ensuring their reliability and safety Each of our drygrinding installations thus represents our tech nological prowess, offering LOESCHEMILLS

2FD{P}PC]854]XQ.jpg)

Analysis and Optimization of Grinding

2022年1月23日 — This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the 2020年11月11日 — roller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Roller mills: Precisely reducing particle size with greater The material falls onto the center of the grinding table; when it leaves the grind ing table it is entrained in the stream of air and car ried to the separator Apart from the mill itself, the largest energy consumer in the Roller mills INFINITY FOR CEMENT EQUIPMENTRoller mills use the centrifugal force of cylindrical grinding rolls to crush material into a uniform particle size and grind, dry, and classify Some of its typical applications include the grinding, drying, and classifying coal , Industrial Roller Mills Williams Crusher

Review on vertical roller mill in cement industry its

2021年1月1日 — Big feed size The vertical roller mill can grind the material of particle size of 5% of the grinding roller diameter The feed size is generally 40 to 100 mm and can reach 120 mm in case of large VRM With the help of the louver ring, the mill inside air flow is guided; as the rollers rotate, the material moves in the centre of the table RMS RollerGrinder builds and services quality grain mill machines and accessories for our customers’ unique applications Our goal when partnering with you is to deploy not only the highest quality machines but also a customized solution for your specific application, along with dependable and expert supportBrewery Mill RMS RollerGrinder2017年9月11日 — A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product Performance Evaluation of Vertical Roller Mill in Cement GrindingMPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, ChinaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

.jpg)

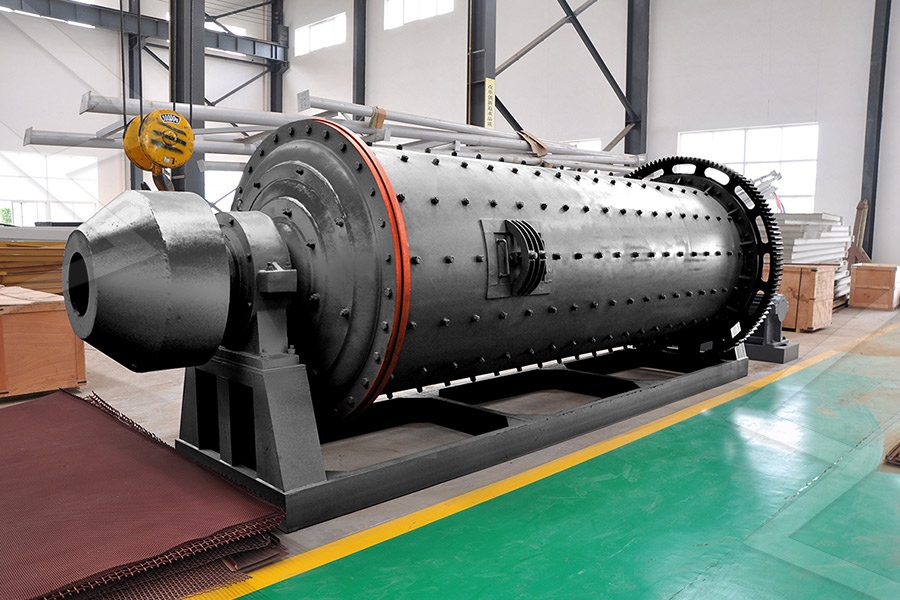

Ball Mills Or Vertical Roller Mills: Which Is Better For Cement Grinding?

2 天之前 — Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to The Raymond® Roller Mill is an airswept vertical ringroll mill withan integral classification system that simultaneously Raymond® Roller Mills are available with grinding ring diameters ranging from 30120 in/ 7603050mm RBS Research Development Center (19618 kB) Raymond Guide to Quality Equipment (28817 kB) Pulverizing Line Raymond® Roller Mills Coperion2009年1月1日 — This example shows that grinding circuit simulation can be used to analyze the production circuit, to optimize the operating parameters and to reduce energy consumption 4 Modeling a vertical roller mill A mathematical model for the grinding process in vertical roller mills has been madeGrinding process within vertical roller mills: experiment and Our CSU and lowprofile mills save horsepower on getting the job done, compared to hammer mills Choose coarse or fine rollers on the top and the bottom of these mills for the perfect crack Our increased roll Grain Roller Mills Grain Processing Equipment

MPS mills for coal grinding Cement Lime

3 Test center GPSE MPS 321 Table 1: MPS mills for solid fuel grinding ordered in the years 1990 to 2013 These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90 % and, on the 2017年7月29日 — 4 Advantages of Polysius roller mills at a glance: xHigh operating reliability and availability, as well as easy system handling, due to the fact that grinding, drying and separation all take place in a single compact unit xConsistently high product quality with minimum energy requirement, due to the integrated highefficiencyPolysius Roller Mills For grinding1 天前 — Lab mills for grinding, pulverizing, chopping samples for routine analysis Find a mill for a variety of sample types, sample capacity, and particle sizes Twotier jar highcapacity laboratory jar mill; 13" roller, 115 VAC/60 Hz EW0414920 $6,94500 USD / Each Add To Cart +ADD TO LIST COMPARE IKA Benchtop A 10 Basic Mill Lab Mills Grinding Mills, Jar Mills, Accessories ColeParmer2013年3月29日 — Unlike the angular shaped particles produced in a roller mill, the pulverizing action of the hammer mill results in particles that are more rounded These smoother surfaces make it easier for the grains to be blended with other components of the feed² So Many Hammer Mills A hammer mill is essentially a steel box surrounding a rotorHammer Mill Application Focus: Grinding Grains for Animal

}@~3SRDG`IA1KP_ICWAA.jpg)

Redundancy and interchangeability – large vertical roller

2017年8月11日 — rollers made it possible to use the existing roller modules from mills that have already been operating successfully for many years The roller module ( Fig 3) of a Loesche mill consists of the grinding roller, the spring system, which transmits its hydraulically applied grinding forces via a lever system (rocker arm) to the grinding roller 2021年2月16日 — Today's roller mills are an essential part of the American food production chain Modern flour production depends on the use of grain roller mills to reduce wheat berries into flour In addition, roller mills are vital to the processing of other grains, including the most important grain in the US today: cornUnderstanding why roller mills have taken Roller Mills: What They Are and Why They're GreatFor a vertical roller mill, the grinding parts are rollers and grinding disc The pressure required for grinding mainly comes from the rollers At present, the loading force is mainly formed by hydraulic pressure The material is fed into the grinding disc from the center or side of the upper housing, and the material layer is formed in the Cement Grinding Machine Selection: Vertical Roller Mill VS Roller Press2024年4月15日 — Some businesses in the coffee industry have been employing roller mills to grind up coffee beans for larger companies For those businesses, the coffee grounds must be a consistent grind, and the roller mill is an optimal way for them to do that Biomass This is a newer industry integrating roller mills One example is biochar This is used as Industrial Roller Mill or Hammer Mill RMS RollerGrinder

Something You Should Know about Three Roller Grinding Mill

Threeroll mill for short, threeroll mill can be divided into two types: experimental threeroll mill and production threeroll mill The threeroll mill is suitable for the manufacture of slurries such as paints, inks, pigments, and plastics The working principle of the threeroller grinder: The threeroller grinder achieves the grinding effect through the mutual extrusion of the 2023年8月17日 — The rollers The OK mill design uses the same swing lever and roller assemblies for either cement or raw applications It also allows the ability to continue using the unique grinding roller profile of the OK cement mill and an optimised spherical grinding profile for raw grinding applications The rollers are in a lifted position when the mill OK™ mill The most reliable and efficient mill for raw and Knowledge Center; Progress with Grinding Aids for Vertical Roller Mills; Cement Admixture SikaGrind® The effect of grinding aids on the comminution of cement is based on the dispersion of fine particles It is a Progress with Grinding Aids for Vertical Roller The power ingesting of a grinding process is 5060% in the cement production power consumption The Vertical Roller Mill (VRM) reduces the power consumption for cement grinding approximately 3040% associated with other grinding mills The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay PROCESS CONTROL FOR CEMENT GRINDING IN VERTICAL ROLLER MILL

Where Your Flour Comes From Roller Stone Milling Explained

2020年3月31日 — Roller mills Nowadays, stone mills are still used by mostly smaller millers As of the early 20th century the majority of millers uses roller mills nowadays These are more efficient and easier to handle Instead of using two round stones that (almost) touch with their flat sides, roller mills using two parallel cylinders2024年8月27日 — GUIKUANG is mainly engaged in the research and development and manufacture of various powder equipment such as vertical roller mills,superfine roller mills, Raymond mills, hydrated lime production lines, ultrfine ring roller mills,separators, crushers, sand making machine,sand and powder integrated grinding machine etc Learn MoreRaymond Mill, Vertical Roller Mill, Sand Making MachineThe differential pressure between the inlet and outlet of the mill (ΔP mill) is an important process variable for the testing of grinding aidsΔP mill reflects the load and the filling level of the mill At unchanged separator settings, the increase of ΔP mill indicates more internal circulations and more fines As a result of the higher ΔP mill, the mill vibration increases Grinding Aids for Vertical Roller Mills Sika2001年10月1日 — Schaefer [2] emphasizes the advantages of dry grinding with a vertical roller mill against conventional grinding plants The feed can be coarser, lower specific energy demand, the 3 rd crushing LOESCHE vertical roller mills for the comminution of

.jpg)

Study on Particle Characteristics of Cement by Vertical Roller Mill

2013年5月1日 — It has been reported that vertical mills, which are widely used in mineral grinding operations, are more energysaving and environmentally friendly than the traditional ball mill, and have the Roller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds Choose the roller mill that best fits your location's needs and gather more information by contacting companies through the form available belowRoller Mills Grain and Feed EquipmentHammer Mill Grinding With over 160 years of industry experience and continued cutting edge research and development, Bühler is proud to present the next generation grinding portfolio, with all new and updated equipment to provide the highest performance and value for your businessHorizontal Hammer Mill Grinding System Bühler GroupOur bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag Its cuttingedge design features consistently deliver the highest quality products with the OK™ Raw and Cement Mill FLSmidth Cement

Research of iron ore grinding in a verticalrollermill

2015年3月15日 — The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemBetween the working surfaces of track and rollers, particle bed comminution takes place A dynamic air separator (3) is located above the grinding 2012年3月1日 — Vertical roller mills are the mills traditionally used for processing granulated blastfurnace slag and for grinding composite cements From the energy aspect they are superior to grinding plant Operating experience with a vertical roller mill for grinding Raymond roller grinding mill is mainly applicable to the grinding and processing of mineral product materials such as metallurgy, building materials, Products center Products center Grinding Equipment Crushing Equipment Accessories Tel: +86(021) +95 Fax: +86(021) EMail:Raymond Roller Grinding MillThe rollers are the most important component of the vertical roller mill They rotate around the grinding table, crushing and grinding the material into fine particles The rollers are made from highquality steel and are usually coated with a wearresistant material to increase their lifespan Grinding Rollers The grinding rollers are a What are the Parts of Vertical Roller Mill ballmillssupplier

.jpg)

More than 400 vertical roller mills for cement and granulated

In the second quarter of 2014 over 300 vertical roller mills of this type were in operation or construction In the last four years, a further 100 mills were sold History The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical airswept grinding mills dates back to Ernst Curt Loesche’s invention2017年8月12日 — assembly raise the grinding rollers prior to commencing grinding, allowing the mill to start with a lower torque (approx 40% of the operating torque), regardless of its filling condition • There is no metallic contact between the grinding rollers and grinding track due to adjustable stop buffers mounted on the millLoesche Grinding Technology for the Power Industry2002年5月9日 — Vertical roller mills offer significant potential for savings when used for finish grinding Two installations in Peru and the Dominican Republic are being examined with specific data on cement production, product fineness, specific power consumption and concrete strength The vertical mill at Cementos Pacasmayo, SA in Peru was Finish grinding with vertical roller millsoperating data2023年6月9日 — We have 20 years experience in servicing and maintaining roller mills and have worked across a wide variety of brands and types of roller mill machinery This exposure has allowed us to identify the pros and cons of various designs and determine the ideal parts and material to engineer our own longerlasting, quality products to achieve Australian Roller Mills Grain milling machinery for corn,

.jpg)

MIAG GmbH Roller Mill MIAG Milling

4 天之前 — The "VWSE" roller mill is used for grinding granular products, eg wheat, spelt, rye, corn, etc In a roller mill, there are always two pairs of rollers that can take on different tasks The drive can be either with one motor per pair of rollers with the appropriate flat belt transmission (standard) or with an individual drive for each 2020年11月11日 — roller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Roller mills: Precisely reducing particle size with greater The material falls onto the center of the grinding table; when it leaves the grind ing table it is entrained in the stream of air and car ried to the separator Apart from the mill itself, the largest energy consumer in the Roller mills INFINITY FOR CEMENT EQUIPMENTRoller mills use the centrifugal force of cylindrical grinding rolls to crush material into a uniform particle size and grind, dry, and classify Some of its typical applications include the grinding, drying, and classifying coal , Industrial Roller Mills Williams Crusher

Review on vertical roller mill in cement industry its

2021年1月1日 — Big feed size The vertical roller mill can grind the material of particle size of 5% of the grinding roller diameter The feed size is generally 40 to 100 mm and can reach 120 mm in case of large VRM With the help of the louver ring, the mill inside air flow is guided; as the rollers rotate, the material moves in the centre of the table RMS RollerGrinder builds and services quality grain mill machines and accessories for our customers’ unique applications Our goal when partnering with you is to deploy not only the highest quality machines but also a customized solution for your specific application, along with dependable and expert supportBrewery Mill RMS RollerGrinder2017年9月11日 — A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product Performance Evaluation of Vertical Roller Mill in Cement GrindingMPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, ChinaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

.jpg)

Ball Mills Or Vertical Roller Mills: Which Is Better For Cement Grinding?

2 天之前 — Vertical roller mills Vs ball mills has long been a raging debate in the cement industry In spite of the fact that vertical roller mills have been around for over ten years now and have gradually become the standard as far as cement manufacturing goes, several cement manufacturers still prefer ball mills for cement production when they want to The Raymond® Roller Mill is an airswept vertical ringroll mill withan integral classification system that simultaneously Raymond® Roller Mills are available with grinding ring diameters ranging from 30120 in/ 7603050mm RBS Research Development Center (19618 kB) Raymond Guide to Quality Equipment (28817 kB) Pulverizing Line Raymond® Roller Mills Coperion2009年1月1日 — This example shows that grinding circuit simulation can be used to analyze the production circuit, to optimize the operating parameters and to reduce energy consumption 4 Modeling a vertical roller mill A mathematical model for the grinding process in vertical roller mills has been madeGrinding process within vertical roller mills: experiment and