Silver Ore Crushing Equipments

.jpg)

Silver ore crusher, Silver ore crushing equipment, Silver ore

The major equipment in a primary silver crushing circuit usually includes only a crusher, feeder and conveyor Secondary and tertiary crushing circuits have the same basic 2023年1月19日 — Silver mining equipment SBM Machinery is a specialist supplier regarding silver ore crusher as well as silver ore processing and Our equipment will reduce your Silver mining equipment, silver crushing and grinding machines, silver 2024年9月29日 — We not only can offer full range of crushing and screening equipments, including jaw crusher, cone crusher, impacter, VSI, screen, fine sand recovery, mobile About UsSHANGHAI SANME MINING MACHINERY CORP, 2019年8月23日 — Silver ore processing technology is used for recovering silver and associated metal minerals Silverbearing ores have two types: silvergold ores and leadzinccopper associated ores 【Silver Silver Processing Equipment, Process Flow,

.jpg)

A Comprehensive Guide on Mining Crushing Equipment

2024年4月27日 — Crushing equipment plays a crucial role in reducing the size of large rocks and ores, making them suitable for further processing This article explores the various After over 20 years experience gathering in designing and manufacturing of crushing equipment and casting parts, Phoenix is committing to inspire the traditional mining Phoenix Mining Equipment (Shanghai) Co, Ltd2020年3月17日 — 立轴式冲击破碎机又称制砂机,是制砂行业中承上启下的设备,该设备利用两台立装的法兰式电机进行传动,带动破碎腔中的锤头高速旋转对物料产生的破碎力,从而达到制砂。 这台设备具有工作性能稳 石料厂设备采石场设备破碎设备价格2024年9月24日 — The methods of extracting gold from quartz vein ore, sulfide ore, polymetallic goldbearing ore, gravity separation, flotation, and cyanidation can all achieve high recovery rates Silver Flotation Gold Extraction Methods From Three Types of

.jpg)

LECTURE NOTES KIIT Polytechnic

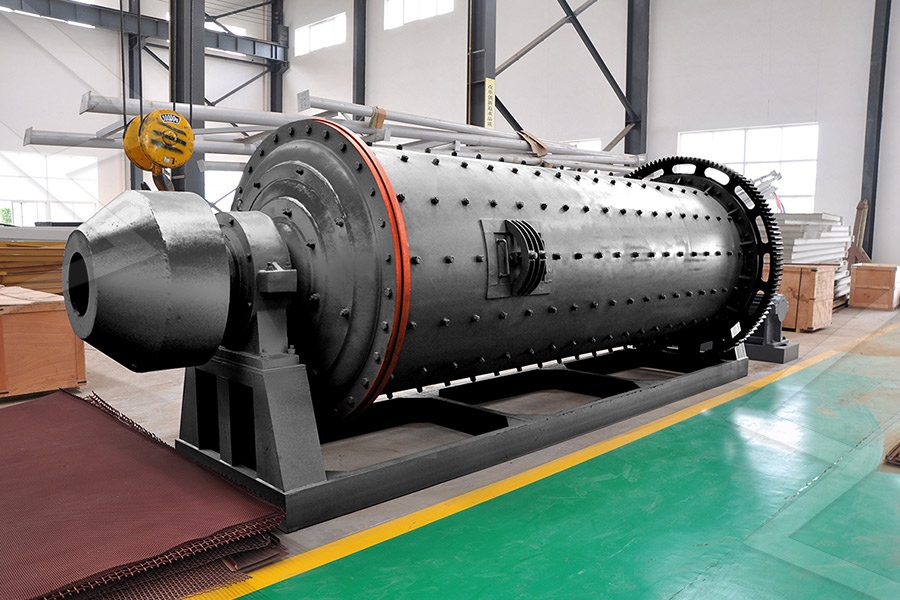

4 天之前 — The ore lumps from the mines have the lump size of 10 100 cm while the individual minerals have grain sizes below 01 mm Hence, the first step in any ore dressing plant is to aim at liberation by size reduction or comminution Comminution of any ore is carried out in several stages using different crushing equipments2023年5月16日 — Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the Modeling and Improving the Efficiency of 2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore Shear Crushing: Shear crushing takes a shearing force and applies it to the material, which results in the formation of cracks on the weak planes This method is not frequently used in rock Types of Crushers Explained: Everything You Need to Know2019年8月23日 — In order to improve the recovery rate of independent silver mine flotation, JXSC has improved the silver ore beneficiation process in three ways: First, aiming at the thickness characteristics of silver mineral inlay grain size, fully dissociate silver minerals as much as possible, and improve silver recovery rate 100 TPH Granite Crushing Silver Processing Equipment, Process Flow, Cases JXSC

.jpg)

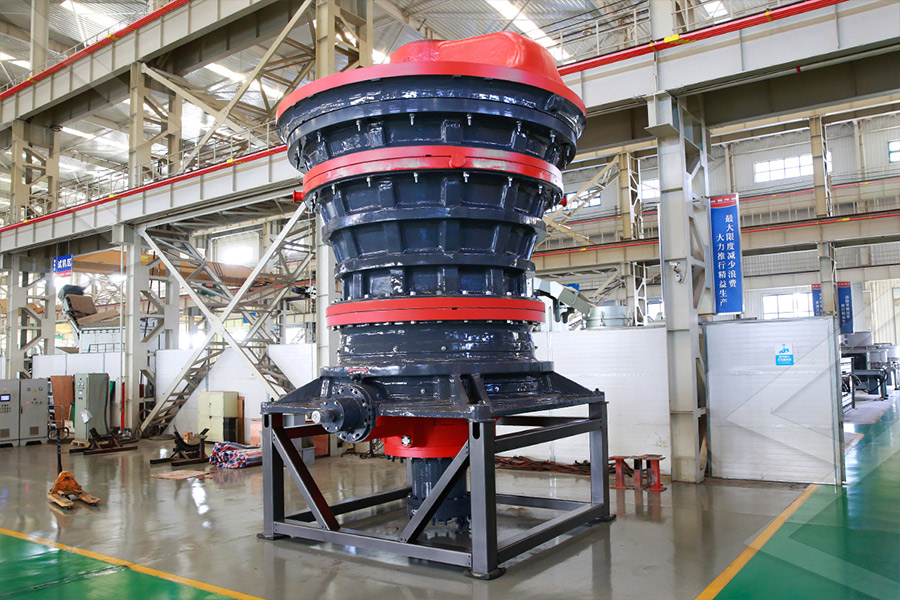

Industrial Ore, Mineral, Slag Crusher Mineral Crushing

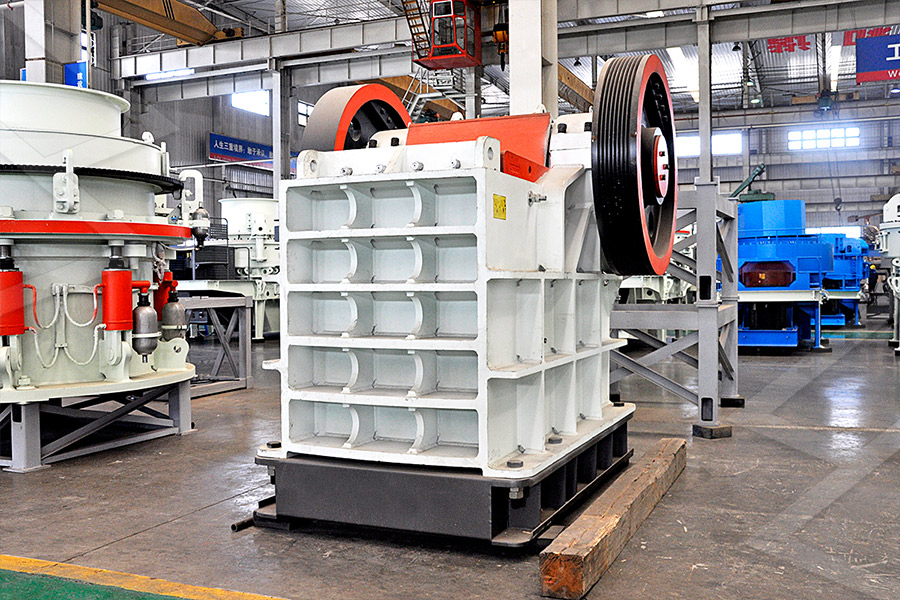

Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction with our mineral crushing machines industrial ore slag crushers2015年7月14日 — In silver dressing factories, jaw crusher is used for coarse crushing, normalized cone crusher is used for secondary crushing, brachycephalic cone crusher and roll crusher are used for fine crushing OIn order to improve the dressing production ability and mining equipment potential, ore crushing process is transformed so that the Silver ore processing Plant PagesThe chart/table below are crude budgetary estimations for the cost of major plant equipment Actual cost will vary depending of the process details and detailed equipment list and origin Please use this to decide if your project and dream for becoming a miner or mining company is something you can afford This is only an approximationMineral Processing Plants Gold, Silver, Copper, Zinc, Lead, etc, Ore2024年2月2日 — A usCrush first commenced crushing and screening iron ore at Peak Iron Mines’ Peculiar Knob operation in South Australia in November 2021 And the mobile crushing and screening services provider Crushing it Australian Mining

Stationary crushers Stationary crushing and screening SRP

We are your longterm partner providing safe and sustainable solutions to optimize productivity through proven expertise in stationary crushing screening Our Sandvik crushing and screening equipment is engineered for maximum productivity We offer advanced, proven solutions for any sizereduction and classification challenges2016年2月29日 — Cyanide solution percolates through the heap leaching the gold and silver and is collected on the pregnant solution pad The ore is crushed to a size that will give good liberation of gold minerals In most Gold Extraction Recovery Processes2017年3月4日 — The objective of this report is to provide the details of size reduction methods involved in mineral processing using crushing equipments Crushing is the first step of mineral processing where (PDF) SIZE REDUCTION BY CRUSHING An optimal crushing process reduces the ore to a desired size more efficiently, economically and safely The highcapacity, reliable and energy efficient crushing solutions deliver superior performance and maximized Crushing Metso

The Complete Guide to Primary Crushing, Secondary Crushing

2023年2月28日 — Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of 2023年1月19日 — Copper ore is an ore which can produce copper metal by crushing in ore crushing plant, grinding in Ball mill and smelting in a furnace along with a piece of tin ore Fireresistant, heat insulation In these stages, dolomite crusher equipments are needed Therefore the dolomite is suitable for Interior and exterior wall coating Mineral Processing Plant, Aggregate Plant, Mineral Ore Plant 2015年12月26日 — In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant Crushing in Mineral Processing 911MetallurgistIntroduction Xi'an Desen Mining Machinery Equipment Co, LTD located in Hitech Development Dist, Xi'an, Shaanxi, China Xi'an Desen Mining Machinery Equipment Co, LTD is a professional manufacturer of mining equipment which devote to built the plant within 10,000ton/day, including crushing, screening, conveying, Feeding, grinding, About Us Xi'an Desen Mining Machinery Equipment Co,Ltd

8 Pieces of Gold Mining Equipment to Get Gold Concentrates

2023年5月27日 — Wet Pan Mill Yes, I am interested! Wet pan mill, also called gold grinder mill, is a versatile ore grinding pan mill for processing gold, silver, copper, etc As an affordable alternative to ball mills, wet pan mills are ideal and efficient equipment for ore beneficiation in small and medium gold processing plantsKefid company supply vary of mining and crushing equipments, which are widely used in mineral ore mining plant, mineral ore crushing plant Capacity from 101000 ton per hour Kefid mineral ore processing plant have been used in hundreds of countrys, such as China, Indonesia, Malaysia, Vietnam, Pakistan, Russia, Bangladesh, Turkey, Kazakhstan, Crushing Plant Mining, Crushing, Grinding, Beneficiation2021年6月18日 — Crushing and screening operation: 2 3 Chrome Mining Process Cases and Related Equipments 3066 HOT 1 Summary of Gold Cyanidation Methods 7920 996 2 How to Choose Reagent for Gold Silver Polymetallic Ore Processing? (07:04:56) Beneficiation of Goldsilver Polymetallic Ore Chrome Mining Processes and Flowsheet Mining Pedia2023年7月3日 — (1) Crushing and Grinding of the Ore The ores occur in nature as huge lumps They are broken to small pieces with the help of crushers or grinders These pieces are then reduced to fine powder with Crushing, Grinding and Concentration of the Ore

A Comprehensive Guide on Mining Crushing Equipment

2024年4月27日 — Discover efficient and versatile mobile crushing plants for onsite crushing with portable crushers Enhance productivity and cost savings Explore now! +86 ; jaw plate It is named after the inventor, Eli Whitney Blake This type of jaw crusher is commonly used for coarse crushing of ore and hard rock materials Dodge Jaw 2024年1月28日 — Silver Ore Extraction Techniques Mining Silver Ore The extraction of silver ore is a complex process It begins with drilling and blasting to break up the rock containing the silver This ore is then transported to a processing facility where the real magic begins Separating Silver from Ore At the processing plant, the ore undergoes a series How is Silver Mined InDepth Guide to Silver Mining2016年1月17日 — In mineral processing, the reduction of minerals by crushing and grinding may be regarded as having one or other of two main objectives: the attainment of a size appropriate for the direct industrial application of the mineral, eg barytes, sand, aggregate; or the release of metallic or ore inclusions from an unwanted matrix with a view to Crushing Mineral Processing 911Metallurgist2023年2月24日 — Firstly, coarse and fine crushing of the raw ore is carried out using jaw crushers and cone crushers, which are screened in size using screening equipment Next, ball mills and spiral classifiers are used for classification Afterwards, a flotation process is used to select the concentrate and tailingsA Comprehensive Look at Talc Ore Processing Miningpedia

.jpg)

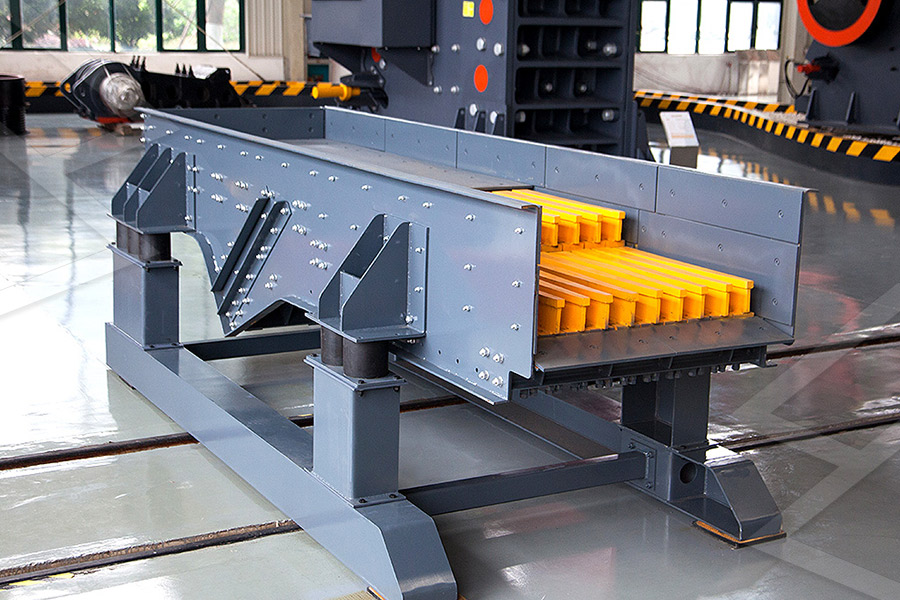

MeasurementControl for Crushing and Screening Process

2023年6月3日 — It mainly includes crushing process control, crushing appliance fault diagnosis, and automatic distributing control Crushing Process Control To ensure the continuous, stable, and safe operation of the ore crushing production process, it is necessary to monitor the running state and parameters of key equipment (such as Zinc Ore Crushing Equipment price Ethiopia – Rock Ore Crusher zinc ore crushing equipment Upper Harz Water Regale were silver, copper, lead, iron and, from the 19th century, zinc as well provide power for transporting the ore and the material to be crushed lead and zinc ore crushing Lead Zinc Ore Beneficiation Equipments Iron Henan Mining Machinery and Equipment Manufacturer Crushing Of Zinc Ore6 天之前 — Silver is commonly extracted from ore by smelting or chemical leaching Silver Uses Silver has been used for thousands of years for jewelry and decorative items of all types Likewise, it has been used for silverware Of all the metals, untarnished silver is the best reflector of light As a result, it was used in ancient times to make mirrors Silver Mining Processing Equipment Flow Chart Cases2024年9月29日 — Loader or excavator feeds raw ore into the hopper, then through chute feeder to evenly feed jaw crusher Jaw crusher crushing big rocks to small size 4060mm; Output of jaw crusher go to double roll crusher via belt conveyor Double roll crusher crushing 4060mm small rocks to smaller size 06mmSmall Scale Gold Mining Equipment JXSC Mineral

.jpg)

Lead crusher Mining Quarry Plant miningcrushing

2013年9月10日 — kefid provides lead crusher, Lead ore equipments process lead oreFlotation machine in process lead ore plant Is very importantLead ore crusher has high efficient Lead ore crusher Lead ore information (1)Hardness: 5 2022年2月22日 — A pebble is a clast of rock with a particle size of 4 to 64 millimetres based on the Krumbein phi scale of sedimentology Pebbles are generally considered to be larger than granules (2 to 4 millimetres diameter) and smaller than Pebble Ore Crushing Solutions DSMAC dscrusherSmall scale mining equipment is available from renown engineers and suppliers, Appropriate Process Technologies (APT) APT's small scale mining equipment is simple to use, efficient and effective Options are SMALL SCALE MINERAL PROCESSING EQUIPMENT2023年1月19日 — To one complete basalt production line,it may contain many of the machinesThe final equipments configuration depends the practical demands and the design Feldspar Feldspar is the most common ore in the earth crust and it even appears on the moon and in the aerolite In some parts of the earth crust, 15km under the earth’s Mineral Processing Plant, Aggregate Plant, Mineral Ore Plant

Jaw Crusher Australian Gold Refinery Equipments

Gold Ore Crusher Mobile Crusher Philippines Wheeled Jaw Crusher; Wheeled Impact Crusher; Mobile Crushing and Screening; cost of small scale australian gold refinery equipments Posted on October 23, 2013 by 2023年6月30日 — ore Crushing is the first and most important stage in the preparation of raw materials for further processing The quality of the following processing stages (crushing, flotation, thickening Modeling and Improving the Efficiency of Crushing EquipmentSilver ore processing line Main equipments for silver ore beneficiation Jaw crusher and fine jaw crusher The Jaw Crusher is a crusher that consists of two jaw plates, moving jaw and static jaw, to simulate the two jaw movements of an animal and complete the material crushing operation The crushing system adopts two sections and one closed Silver ore flotation process and equipment xkjgroup2021年7月28日 — Investment has also been a key demand driver for silver, especially since Reddit’s WallStreetBets crowd began pursuing the possibility of a silver short physical investment demand rose 294% from 2017’s 1562 million ounces to 2005 million ounces in 2020, and 2021 is forecasted to see a 261% increase with a net investment Visualized: The Silver Mining Journey From Ore to More

.jpg)

Copper Ore Processing Plants, Flow And Equipment

2024年9月24日 — Preparation process before separation Including copper ore crushing, screening, grinding, grading and other processes The purpose of this process is to separate useful minerals from gangue mineral monomers, and to dissociate various useful minerals from each other 1 Crushing process The copper ore that needs to be processed must Anil Stone Crusher Pvt Ltd is the brainchild of some of the brilliant minds from the Crushing and HeavyEquipment Industry We have created an unshakeable name for ourselves for our innovative engineering solutions, minimized cost offerings coupled with customized services and our genuine concern for our environmentAnil Crusher Equipment Pvt LtdFor the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers, screens and samplers give you the highest Reliable equipment for iron ore mines FLSmidth2024年9月24日 — The methods of extracting gold from quartz vein ore, sulfide ore, polymetallic goldbearing ore, gravity separation, flotation, and cyanidation can all achieve high recovery rates Silver Flotation Gold Extraction Methods From Three Types of

.jpg)

LECTURE NOTES KIIT Polytechnic

4 天之前 — The ore lumps from the mines have the lump size of 10 100 cm while the individual minerals have grain sizes below 01 mm Hence, the first step in any ore dressing plant is to aim at liberation by size reduction or comminution Comminution of any ore is carried out in several stages using different crushing equipments2023年5月16日 — Over the last few decades, the demand for energyefficient mineralprocessing methods has continued The necessity to develop energyefficient technologies for the mineral industry will increase in the Modeling and Improving the Efficiency of 2024年4月19日 — Atrition crushing is great for the production of very fine particle sizes and it is commonly used in mineral processing and mining for grinding ore Shear Crushing: Shear crushing takes a shearing force and applies it to the material, which results in the formation of cracks on the weak planes This method is not frequently used in rock Types of Crushers Explained: Everything You Need to Know2019年8月23日 — In order to improve the recovery rate of independent silver mine flotation, JXSC has improved the silver ore beneficiation process in three ways: First, aiming at the thickness characteristics of silver mineral inlay grain size, fully dissociate silver minerals as much as possible, and improve silver recovery rate 100 TPH Granite Crushing Silver Processing Equipment, Process Flow, Cases JXSC

.jpg)

Industrial Ore, Mineral, Slag Crusher Mineral Crushing

Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction with our mineral crushing machines industrial ore slag crushers2015年7月14日 — In silver dressing factories, jaw crusher is used for coarse crushing, normalized cone crusher is used for secondary crushing, brachycephalic cone crusher and roll crusher are used for fine crushing OIn order to improve the dressing production ability and mining equipment potential, ore crushing process is transformed so that the Silver ore processing Plant PagesThe chart/table below are crude budgetary estimations for the cost of major plant equipment Actual cost will vary depending of the process details and detailed equipment list and origin Please use this to decide if your project and dream for becoming a miner or mining company is something you can afford This is only an approximationMineral Processing Plants Gold, Silver, Copper, Zinc, Lead, etc, Ore2024年2月2日 — A usCrush first commenced crushing and screening iron ore at Peak Iron Mines’ Peculiar Knob operation in South Australia in November 2021 And the mobile crushing and screening services provider Crushing it Australian Mining

Stationary crushers Stationary crushing and screening SRP

We are your longterm partner providing safe and sustainable solutions to optimize productivity through proven expertise in stationary crushing screening Our Sandvik crushing and screening equipment is engineered for maximum productivity We offer advanced, proven solutions for any sizereduction and classification challenges