MILL BALL

.jpg)

球磨机 百度百科

2023年8月15日 — 中文名 球磨机 外文名 ball mill 分 类 水泥、管式、超细层压等 能耗低 建材及化工等行业 价格昂贵 目录 1 简介 2 工作原理 3 球磨机装球 4 机械结构 5 球磨机配件 6 提高效率 7 机械分类 水泥球磨 2022年9月28日 — 球磨,英文ballmilling,是一种主要以球为介质,利用撞击、挤压、摩擦方式来实现物料粉碎的一种研磨方式。 在球磨的过程中,被赋予动能的研磨球会在密封的容器内进行高速运动,进而对物料进行碰 球磨是什么?实验室球磨工艺介绍 知乎2020年4月19日 — 球磨方式 球磨机根据工作方式的不同,有干式球磨机和湿式球磨机之分,根据不同的行业以及物料的特性使用不同的球磨方式。 干式球磨 是直接将物料输送到 球磨是干什么的,详解球磨工艺,解开我多年的疑惑! 知乎4 大关键区别说明 球磨机和 SAG(半自磨)磨机的主要区别在于它们的运行机制和研磨材料。 球磨机利用钢棒、钢球或类似介质研磨物料。 SAG 磨机则使用大块矿石和钢球进行 球磨机和 Sag 磨机有何区别?4 大关键区别说明 Kintek

Ball Mill an overview ScienceDirect Topics

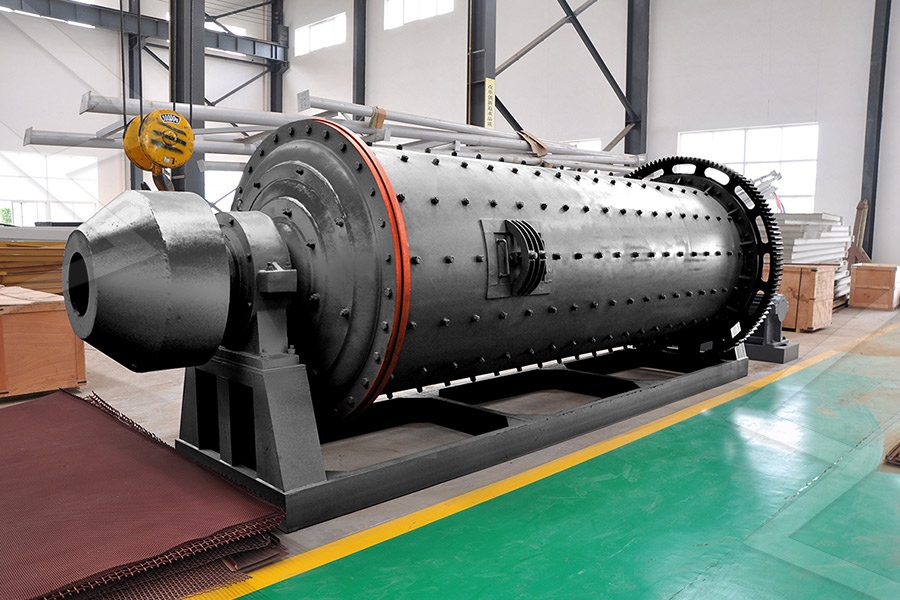

Ball mills are commonly used for crushing and grinding the materials into an extremely fine form The ball mill contains a hollow cylindrical shell that rotates about its axis This 突出特点 高品质 独特的珠磨机技术 Nova S 球磨机可适用于各种浆料的精磨解决方案,例如代脂、涂抹酱、馅料和涂层奶油、可可浆料、坚果酱及其他脂性浆料。 独特的研磨腔可在低温下实现一步研磨,确保您的产品具 Nova S 球磨机 布勒集团 Bühler GroupThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material 行星式球磨仪PM100德国RETSCH(莱驰)研磨仪 The ball mill has the advantages of high crushing ratio, good reliability, strong adaptability and large processing capacity Our ball mill can be divided into dry type and wet type Ball Mill北方重工

.jpg)

Ball Mill SpringerLink

2023年4月30日 — Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, XRDMill McCrone是专门为后续X射线衍射(XRD)分析的样品制备而开发的。 该研磨仪可用于地质学、化学、矿物学和材料科学、质量控制以及科学研究的应用。Retsch : 粉碎设备 : 球磨仪 : XRDMill McCrone2024年8月8日 — Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding Media {{lastDate}} Introduction In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, Ball Mill Success: A StepbyStep Guide to 2019年8月14日 — The gravel ball mill adopts porcelain material or granite as the lining board, which is widely used in the field of colored cement, white cement and ceramics 3 According to the discharging method of ball mill: • End discharge ball mill: This ball mill takes its head and end as the inlet and outlet respectivelyThe Ultimate Guide to Ball Mills Miningpedia

.jpg)

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or An industrial ball mill is a type of ball mill used in largescale production settings It is designed to process large volumes of material and can be used for both wet and dry grinding Industrial ball mills are typically made of steel, and the lining material is selected based on the type of material being processed 4 Conical Ball MillHow to Choose the Right Type of Ball Mill for Your ApplicationBall mill adalah mesin penggiling yang digunakan untuk menghancurkan dan menggiling bahan menjadi bubuk halus Ball mill biasa digunakan dalam industri pertambangan, kimia, pengolahan makanan, dan lainlainBall Mill: Fungsi, Cara Kerja, Jenis Dan Perawatannya AlwepoMicro Ball Mill GT300Order Information Item No Description Please order grinding jars and balls separately 248900001 Micro Ball Mill GT300, 220V, 50/60Hz 248900003 Micro Ball Mil GT300, metal plate cover, 220V,50/60Hz Grinding jars (screw threadsMicro Ball Mill GT300 Beijing Grinder Instrument Co,Ltd

BALL MILLS Fritsch Milling and Sizing

2024年9月26日 — BALL MILLS Laboratory Ball Mills are used for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle sizes The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding 2023年4月30日 — Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials Ball mill is the key equipment for crushing materials after they are crushed It is widely used in cement, silicate products, Ball Mill SpringerLink2023年6月23日 — Applications for Ball Nose End Mills Ball nose end mills are commonly used in aerospace, automotive, and medical industries They are ideal for producing complex geometries and shapes with tight tolerances, such as turbine blades, medical implants, and automotive parts Ball nose end mills are also great for 3D contouring and Everything You Need to Know About Ball Nose End Mills2024年9月22日 — A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, and ceramics It works on the principle of impact and friction between rotating balls and the powder materials The ball mill consists of a rotating drum and a hollow cylinder filled with grinding media, typically Understanding the mechanism: How does a ball mill work?

Pengertian Ball Mill dalam Proses Manufaktur PT Nihona

2023年10月27日 — Ball mill juga digunakan dalam pembuatan bubuk, pewarna, keramik, dan banyak produk lainnya Jenisjenis Ball Mill Ada beberapa jenis ball mill yang digunakan dalam berbagai industri Beberapa di antaranya mencakup: 1 Ball Mill Basah (Wet Ball Mill)Labmate’s Ball Mill is an advanced material blending device that utilizes rotating steel balls to create a finely homogenized blend of materials within a precisely controlled setting It is equipped with a liquid oil gauge to enhance efficiency and reduce noise levels This mill is equipped with a single container and operates within a speed Laboratory Ball Mill LabmateThe Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material 行星式球磨仪PM100德国RETSCH(莱驰)研磨仪 The Planetary Ball Mill PM 200 is a powerful benchtop model with 2 grinding stations for grinding jars with a nominal volume of 12 ml to 125 ml The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short Retsch : 粉碎设备 : 球磨仪 : PM 200

.jpg)

What are Mill Balls Made of? ball mills supplier

Mill balls are an essential component of the ball milling process, which involves the use of a rotating cylindrical vessel filled with large pieces of material, such as ore, ceramic, or metal balls, to crush and grind the material into fine powderThe type and quality of the mill balls used in the process play a significant role in determining the efficiency and effectiveness 2020年3月10日 — Materials are added to the ball mill, at which point the balls knock around inside the mill How a Ball Mill Works Ball mills work by using balls to grind materials Materials such as iron ore, pain and ceramics are added to the ball mill Next, the ball mill is activated so that it rotates — either on its vertical or horizontal axis As the What Is a Ball Mill? Blog Posts OneMonroe2024年9月28日 — Ball Mill machine changes the intrinsic grinding mill structureIts body and ground plank are an integral whole So when fixing, it can be lowered on a plane surface once only Use double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%Ball Mill clirikchina2012年6月1日 — Ball mills can grind a wide range of materials, including metals, ceramics, and polymers, and can operate on a variety of scales, from laboratory to industrial (Monov et al 2013) The produced (PDF) Grinding in Ball Mills: Modeling and Process Control

Ball Mills Glen Mills, Inc

2024年9月7日 — The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times The PM 400 is a robust floor model with 4 grinding stations You may also be interested in the High Energy Ball Mill Emax, an entirely new type of mill for high energy input The unique combination of high 2024年9月14日 — Cara Kerja Mesin Ball Mill Cara kerja Mesin Ball Mill dimulai dengan memasukkan bahanbahan keras ke dalam mesin melalui kerucut di salah satu sisi Pada wadah tersebut, sudah dipasang ripple scaleboard dan Mengenal Mesin Ball Mill : Penjelasan Lengkap Empat PilarIn fact, in the same application a Vertimill® has 50% less footprint than a ball mill Lower operating cost Vertimill® is an energy efficient grinding machine They tend to grind more efficiently than, for example, ball mills Vertimill® MetsoPlanetary ball mills are ideally suited for tasks in research like mechanochemistry (mechanosynthesis, mechanical alloying and mechanocatalysis), or ultrafine colloidal grinding on a nanometer scale, Planetary Ball Mills RETSCH fine grinding of

球磨是什么?实验室球磨工艺介绍 知乎

2022年9月28日 — 球磨,英文ballmilling,是一种主要以球为介质,利用撞击、挤压、摩擦方式来实现物料粉碎的一种研磨方式。 在球磨的过程中,被赋予动能的研磨球会在密封的容器内进行高速运动,进而对物料进行碰 The proven classical option for cement grinding Whether employed as a twocompartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding Used in combination with the sepol® highefficiency separator, Ball Mill thyssenkrupp Polysius2024年5月27日 — The General Function of Ball Mills A ball mill is a grinder used for grinding and blending materials for mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering Appearance Ball mills have various designs and functions, ranging from laboratoryscale versions to large industrial modelsBall Mills in the Mineral Processing Industry MechProTechIn fact we design, build and install ball mills which are specially adapted to grind hard and even extremely abrasive materials Advantages of the ball mill Adjustable grain size distribution When operating on the open circuit principle, the product fineness and grain size distribution are adjusted via the peripheral material discharge In Ball mills for various applications Gebr Pfeiffer

Grinding ball Magotteaux

Ball Mill Overview A ball mill is a type of grinding machine that uses balls to crush and grind material The ball mill is made up of a cylinder called the mill shell that turns on a horizontal axis The mill is filled to a certain filling degree with balls and the mill shell is protected by liners The materials to be reduced in size are An inefficient ball mill is a major expense and could even cost you product quality The best ball mills enable you to achieve the desired fineness quickly and efficiently, with minimum energy expenditure and low maintenance With more than 4000 references worldwide, the FLSmidth ball mill is proven to do just thatBall mills FLSmidth CementA ball mill is a cylindrical machine that rotates around a horizontal axis and is filled with grinding media such as ceramic, steel or glass beads The material to be ground is loaded into the drum along with the grinding media and rotated until the desired particle size is A Comprehensive Guide to Finding the Best Ball Mill for Sale2024年9月22日 — The rotational speed of the ball mill drum directly affects the milling process Higher speeds increase the kinetic energy of the grinding media, resulting in more violent collisions and finer grinding outcomes However, excessively high speeds may cause excessive wear and tear on the mill components 3 Fill RateExploring ball milling theory: A comprehensive guide

Ball Mill Manufacturer Neumann Machinery

Founded in 1984 with the acquisition of the EIMCO ball, pebble and rod mill product lines Neumann Machinery Company (NMC) is headquartered in West Jordan, Utah, in the USA just 14 miles south of Salt Lake City3 天之前 — The reliability of a ball mill is crucial for the seamless operation of ore processing and other industrial plants, where unexpected equipment failure or downtime can result in significant financial losses and reduced production efficiency Thus, this paper examined a hybrid method for identifying critical failure modes in a ball mill using the Failure Modes, A Hybrid Method for Identifying Critical Failure Modes in a Ball MillOur ball mills are designed according to the overall advantages and disadvantages of the open circuit comminution system For the equipment, we adopt bearings with both film fluid lubrication and hydrodynamic lubrication as well as bearings with hydrodynamic lubrication only, diversified types of driving units, new abrasionresistant materials and Ball MillSinomaLiyang Heavy Machinery Co, Ltd7900L 湿式ボールミル 3Dイメージ及び粉砕シミュレーション/ 7900L Ball Mill Wet type 3D images and milling simulation Contact お問い合わせ‧お⾒積りはこちら お問い合わせ‧お⾒積りはお電話、 またはお問い合わせフォームよりお問い合わせください。 25 ボールミルの基礎知識 【公式】中工精機株式会社創業100年

Planetary Ball Mill PM 100 RETSCH highest fineness

The Planetary Ball Mill PM 100 is a powerful benchtop model with a single grinding station and an easytouse counterweight which compensates masses up to 8 kg It allows for grinding up to 220 ml sample material per batch2023年10月10日 — The Autogenous Mill remains an integral part of the milling process in many mining operations today Its unique ability to take advantage of natural material properties sets it apart from other types of mills available in the market Ball Mill The ball mill is one of the most commonly used grinding machines in various industriesUnderstanding the SAG Mill in Copper Ore Mining ProcessBall mills are furthermore characterized by significant differences in the sizes of available grinding jars Retsch offers mills with jar capacities from 15 ml up to 150 l and balls are available from 01 mm to 40 mm, see Figure 2 A third and very important which also Retsch : 产品 : 粉碎设备 : 球磨仪2024年1月28日 — 1 Cylindrical Shell: The ball mill consists of a hollow cylindrical shell that rotates about its axis The shell is usually made of steel, stainless steel, or rubber 2 Liners: An abrasionresistant material such as manganese steel or rubber typically lines the inner surface of the cylindrical shell to protect it from wear due to the grinding actionBall mill: Principles, construction, working, uses, merits, and

Ball Mill Success: A StepbyStep Guide to

2024年8月8日 — Ball Mill Success: A StepbyStep Guide to Choosing the Right Grinding Media {{lastDate}} Introduction In the intricate dance of ball milling, where raw materials are transformed into finely milled particles, 2019年8月14日 — The gravel ball mill adopts porcelain material or granite as the lining board, which is widely used in the field of colored cement, white cement and ceramics 3 According to the discharging method of ball mill: • End discharge ball mill: This ball mill takes its head and end as the inlet and outlet respectivelyThe Ultimate Guide to Ball Mills MiningpediaThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or Ball Mill an overview ScienceDirect TopicsAn industrial ball mill is a type of ball mill used in largescale production settings It is designed to process large volumes of material and can be used for both wet and dry grinding Industrial ball mills are typically made of steel, and the lining material is selected based on the type of material being processed 4 Conical Ball MillHow to Choose the Right Type of Ball Mill for Your Application

.jpg)

Ball Mill: Fungsi, Cara Kerja, Jenis Dan Perawatannya Alwepo

alwepo, Ball Mill merupakan alat yang di gunakan untuk menghaluskan bahan, banyak di gunakan di pabrik semen, industri kosmetik, industri medis dan masih Bahan yang akan digiling dimasukkan ke dalam silinder ball mill yang berputar secara horizontalMicro Ball Mill GT300Order Information Item No Description Please order grinding jars and balls separately 248900001 Micro Ball Mill GT300, 220V, 50/60Hz 248900003 Micro Ball Mil GT300, metal plate cover, 220V,50/60Hz Grinding jars (screw threadsMicro Ball Mill GT300 Beijing Grinder Instrument Co,Ltd2024年9月26日 — BALL MILLS Laboratory Ball Mills are used for rapid batchwise comminution of mediumhard, soft, brittle, fibrous, temperaturesensitive and moist samples down to the finest particle sizes The comminution of the material to be ground takes place through impact and friction between the grinding balls and the inside wall of the grinding BALL MILLS Fritsch Milling and Sizing2023年4月30日 — Ball mill is a type of grinding equipment that uses the rotary cylinder to bring the grinding medium and materials to a certain height and make them squeeze, impact, and grind and peel each other to grind materials Ball mill is the key equipment for crushing materials after they are crushed It is widely used in cement, silicate products, Ball Mill SpringerLink

.jpg)

Everything You Need to Know About Ball Nose End Mills

2023年6月23日 — Applications for Ball Nose End Mills Ball nose end mills are commonly used in aerospace, automotive, and medical industries They are ideal for producing complex geometries and shapes with tight tolerances, such as turbine blades, medical implants, and automotive parts Ball nose end mills are also great for 3D contouring and 2024年9月22日 — A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, and ceramics It works on the principle of impact and friction between rotating balls and the powder materials The ball mill consists of a rotating drum and a hollow cylinder filled with grinding media, typically Understanding the mechanism: How does a ball mill work?