Single Deck Vibrating Screen Coal Washery Wiki

.jpg)

Tips and Techniques for Operating and

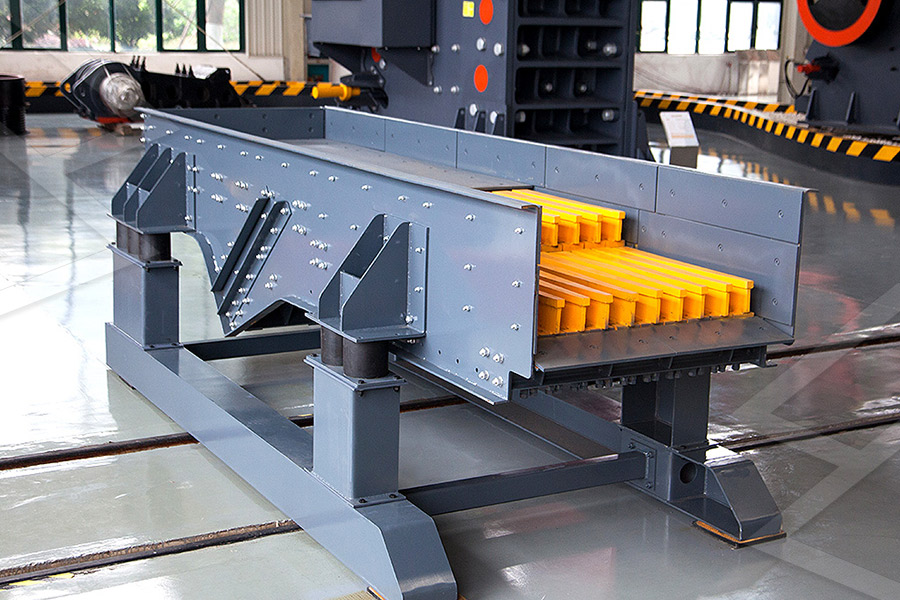

2024年5月3日 — Horizontal vibrating screens are a core component for magnetite recovery and material dewatering processes Its design focuses on highvolume processing in limited spaces while ensuring reliability2023年9月29日 — Vibrating dewatering screens (highfrequency screens) are normally linearmotion, either horizontal or inclined at 5° to 7° upwards with a back plate sloped at 45° to the rest of the screen deck The back plate All Screens Are Not Created Equal Coal Age2020年2月10日 — On a multislope screen, the majority of the screening takes place on the first 8 ft to 12 ft of the deck and the last 4 ft to 8 ft of the deck is used for finished screening Tabor multislope screens can be used for Selection Tips for Vibrating Screens Coal Age2019年8月12日 — A new vibrating screen was developed with a circular mode of vibration for dry screening of moist coal of size fraction −3 + 1 mm Screen mesh of 2 mm aperture Evaluation of a new vibrating screen for dry screening fine coal

What is a vibrating screen in coal handling plant?

2024年3月11日 — Vibrating Screen play a crucial role in coal handling plants by efficiently sorting and separating coal particles of various sizes This article aims to provide a Vibrating screen centrifuges for coal screening from Multotec achieve longlasting performance in the toughest coal dewatering applications This is achieved with a Coal Screening Equipment Multotec2015年12月10日 — In view of this, single deck vibrating screen was inbuilt with large screen surface structure and highly efficient and capacitive motors in order to achieve the Review of vibrating screen development trends: Linking the 2019年4月1日 — A large vibrating screen is crucial to advancing the large scale coal preparation for the clean and efficient utilization of coal A comprehensive review of A review on the advanced design techniques and methods of vibrating

.jpg)

INTELLIGENT SOLUTIONS FOR SCREENING BULK

2023年2月1日 — The range of screening machines from Binder+Co covers conventional screens such as circular motion and linear motion vibrating screens through to special Screening is an indispensable unit operation that is used extensively in many industries to separate particulate materials into different size fractions A banana screen has high screeningSchematic of coal screening processes for (ab) 2023年9月1日 — Benefits of Vibrating Screens Vibratory screens are one of the main types of industrial screening equipment There are several mechanical screening solutions available across the solid waste management, recycling, and aggregate industries; however, vibrating screens offer a number of unique advantages that make them a firstline option What Is A Vibrating Screen? HUATAO GROUPWith over 400 sets of largescale vibrating screens being shipped to customers every year, AURY has become a major provider of vibrating screen to the mining industry in the world Full line of vibrating screens Vibrating Screens AURY Australia

.jpg)

Horizontal Screen by Don Valley Engineering

Single Deck Screens, Twin Deck Screens, Triple / MultiDeck Screen; Multi Angle Screens, Banana Screens, Quarry Screens, Coal Screens, Potash Screens, Wash Screens, Wet Screening Bespoke Vibrating Screen single deck vibrating screen coal washery wiki Basalt Crusher we can divide stone crushers into marble crusher, quartz crusher, limestone it's feeding style incoporates material single impact crusher l t size appm 1822; new innovation in crushing and screening CGM crusher quarryappm 1822 limestone crusher material combination2024年9月18日 — Simply dumping washery rejects on vacant land adjacent to a coal washery is fraught with many problems (Pal et al2012),such as: Creates unsightly waste coal piles that occupy land that could otherwise be put to more useful purposes;coal washery equipments supplierCoal washery suppliers in India,for en/163/coal washery grindingmd at main lbsid/en GitHubEstablished in the year 2019, we “John Finlay India Private Limited” are a prominent firm that is engaged in Importer and Manufacturer a wide range of Vibration Screen, Magnetic Separator, etc Located in Ahmedabad (Gujarat, India), we are a PvtLimited Company firm and manufacture the offered products as per the set industry norms Our valued clients Importer of Motorized Vibrating Screen Dry Coal Washery

.jpg)

Evaluation of a new vibrating screen for dry screening fine coal

2019年8月12日 — The circular mode of vibration provided to the screen deck will incorporate the inertial force on the particle in the screen deck, reducing screen clogging The present study involves the analysis of the screening performance of the new vibrating screen with the coal feed of varying moisture content of 4%, 6% and 8%Condition:New Size:30 x 60 x 120Inch; Type:Other, Deck Vibrating Screen Capacity:15500 Ton/day Material:Stainless Steel Shape:Other, Rectangle Width:1200 Millimeter (mm) Voltage:220660 Volt (v) Supply Ability:10 Per Month Delivery Time:30 DaysVibrating Screen Single Deck Vibrating Screen rollcon2023年8月2日 — The number of screen decks, motor power, wires, and springs may vary depending on the type and the size of the stone and mineral materials to be screened, and the desired capacity Vibrating screen is widely used in mining metallurgy, coal, building materials, chemical industry, cement, glass, grain, medicine and other industries due to Basic concepts of vibrating screens: What they are, what they single deck vibrating screen coal washery wiki for 5year terms which are renewable IDM Members' meetings for 2022 will be held from 12h45 to 14h30A zoom link or venue to be sent out before the timesingle deck vibrating screen coal washery wiki

.jpg)

What is a vibrating screen in coal handling plant?

2024年3月11日 — Introduction: Vibrating Screen play a crucial role in coal handling plants by efficiently sorting and separating coal particles of various sizes This article aims to provide a comprehensive overview of vibrating screens, their operation, types, applications, and importance in coal handling plants Understanding Vibrating Screens: Vibrating screens Inclined Vibrating Screen for Coal Processing, Star Trace offers turnkey solutions for coal processing plants Toggle navigation Star Trace The standard range of screens from 300x900mm to 3000x9000mm in single and multi deck configuration Our Other Links vibrating design exporters globally india plants manufacturers sale screen suppliers Inclined Vibrating Screen Coal Processing Star Trace Pvt LtdManufacturer of Vibrating Screen Single Deck Vibrating Screen, Double Deck Vibrating Screen, MS Rotary Screen offered by Star Material Handling Projects, New Delhi, Delhi Send 85% Response Rate Our range is extensively used in coal dressing, metallurgy, mine, power station and chemical industry Vibrating Screen Single Deck Vibrating Screen Vibrating Deck Screens For SAle Vibratory deck screens or vibrating screens are designed for use in many industries including construction, forestry, landscaping, food and horticulture Easy to load with a suitable loading bucket, the screen vibrates to separate and grade various materials by size and can be used to improve or solve many product handling Vibrating Deck Screens For SAle Welmac UK

A review on the advanced design techniques and methods of vibrating

2019年4月1日 — A large vibrating screen is crucial to advancing the large scale coal preparation for the clean and efficient utilization of coal A comprehensive review of advanced design techniques and methods for a vibrating screen have been presented Almost 71% of all the literature were published during last five years (2)2023年9月1日 — The aggregate vibrating screen works by vibrating the screen mesh, which allows the smaller particles to fall through the openings while the larger particles remain on the screen The screen mesh can be made of various materials such as stainless steel, highstrength carbon steel, or polyurethaneHow To Size and Select a Vibrating Screen for an Aggregate Write better code with AI Code review Manage code changes2022/sbm deck vibrating screen coal minemd at mainSingle deck vibrating screen machines are commonly used as oversize product screeners, polishing screeners, or scalping screens JH provides a full range of sizes from 4′ (1016 mm) wide x 5′ (1270 mm) long up to 7′ (1778 mm) x 25′ (6350 mm) long, designed in 5′ (1270 mm) length incrementsSingle Deck Vibrating Screen Machines JH Equipment

sbm/sbm coal washery equipments vibrating screensmd at

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki ActivitySingle Deck Screen,Buy Quality Single Deck Screen from Single Deck Screen, 24" Single Deck Vibro Screen for Scalping Granule Sugar Model ZDM1500*5600 singledeck vibrating screen for oreSingle Deck Scalping Screen For Iron Ore Crusher2018年3月1日 — Using the particle swarm algorithm to support the vector regression model for global optimization, the parameters of the doubledeck variable screen surface vibrating screen further optimized to Impact of screening coals on screen surface and multiindex It consists of a single screen deck that vibrates in a circular motion, allowing particles to pass through the openings in the screen deck based on their size When manufacturing single deck vibrating screens with various sizes (12FT, 16FT, 20FT, 26FT long) as requested by customers, the process typically involves the following steps:Single Deck Vibrating Screen Luen Seng Foundry (M) Sdn

.jpg)

Executive Summary of Draft EIA/EMP for Proposed 09

2023年11月20日 — The Coal washery project has now been categorized as Orange Category project as per the Press note of MOEFCC dated 05thMarch 2016 and Industrial Sectors UnderRed, Orange, Green and White Categories 0 to 50 mm crushed coal is again forwarded to another similar single deck vibrating screen for2015年7月26日 — The Vibrating Screen is available in single and multiple deck units for floor mounting or suspension The side panels are equipped with flanges containing precision punched bolt holes so that an additional deck may be added in the future by merely bolting the new deck either on the top or the bottom of the original deck Double Deck Vibrating Screen Working Principle 911Metallurgist2018年10月5日 — 2000 to 2500 tones per day at Bhojudih Coal Washery through Rail Raw coal is carried from BOBR hopper to Single Roll crusher by belt conveyor and crushed down to 75 mm size coal and stacked in the raw coal stock Pile For washing, coal is reclaimed from raw coal Stock Pile and fed to vibrating Screen of 25mm aperture sizeBHOJUDIH COAL WASHERY environmentclearancenicStar Material Handling Projects Offering Stainless Steel Single Deck Vibrating Screen at Rs 65000 in New Delhi, Delhi Get Vibrating Screens at lowest price ID: Our range is extensively used in coal dressing, metallurgy, mine, power station and chemical industry Our efficient screening machines are best suited for the Stainless Steel Single Deck Vibrating Screen IndiaMART

.jpg)

VIBRATING SCREEN MBE

Design and function MBE Coal Mineral Technology USK (Circular vibrating screen), USL(Linear vibrating screen) and VSL (High Frequency Screen) with throughputs from 15 to 800 TPHare the result of our constant research and development, based on many years of experience in the construction and manufacture of screening machines, which allows our 2023年11月20日 — PROPOSED 2 X 2 MTPA COAL WASHERY (Wet Process) at Village Batari, Tehsil Khatgora, District Korba, State 0 to 50 mm crushed coal is again forwarded to another similar single deck vibrating screen for screening to 0 to 6 mm and + 6 mm to 50 mm e) 0 to 6 mm fine coal is forwarded to bunker as explained above and +6 PROPOSED 2 X 2 MTPA COAL WASHERY (Wet Process)2023年9月29日 — Vibrating dewatering screens (highfrequency screens) are normally linearmotion, either horizontal or inclined at 5° to 7° upwards with a back plate sloped at 45° to the rest of the screen deck The back plate All Screens Are Not Created Equal Coal Age{"payload":{"allShortcutsEnabled":false,"fileTree":{"archives":{"items":[{"name":"1html","path":"archives/1html","contentType":"file"},{"name":"10html","path GitHub

Executive Summary of Draft Environmental Impact

2015年11月24日 — a) ROM coal, from ramp, will be fed to a feed hopper fitted with 250 mm inclined grating +250 mm coal will be removed at one side and 250 mm will be collected in a feed hopper A reciprocating feeder is provided beneath the feed hopper b) 0 to 250 mm size coal is forwarded to a double deck vibrating screen where 0 to 6 mm fine coal2014年7月22日 — Used as a light duty primary or for finished product screening, screen designs can include single, double, or triple deck and include inclines of between 1530 degrees As with all other of Hawk Machinery’s vibrating screens, they are able to run continuously for 24 hours per day, 7 days a week and 365 days a yearVIBRATING SCREENS Hawk MachineryKRL/EDSingle deckKRL/DDDouble deckSBM Type Perfect Balanced Screen Perfect Balanced Screens sugar, abrasives, coal powder, alumina, and more Resonant type elastic drive using 3phase induction motor and eccentric shaft SBM Type Perfect Balanced Screen: RVS Type Rotary Vibrating Screen: 4P: 2~4: 1450/1710 *2: Tapping ball is Vibrating Screens SINFONIA TECHNOLOGYFor example as single or multipledecks The screens are equipped with reliable DF force exciters, which have a particularly long service life, provide low noise development and require minimum maintenance The applications are wideranging Linear vibrating screens are used in the pit, quarry, coal, ore and steel industriesLinear vibrating screens LinaClass® Qlar

Single Deck HST Deister Machine Company, Inc

2024年9月25日 — Dimensions: Single deck, Widths: 3' to 6', Lengths: 6' to 18' The single deck HST has the vibrating mechanism located above the deck All HS series models utilize proper depth of material bed management in combination with high Gforce operation resulting in optimum separation of fine materials2023年9月1日 — Benefits of Vibrating Screens Vibratory screens are one of the main types of industrial screening equipment There are several mechanical screening solutions available across the solid waste management, recycling, and aggregate industries; however, vibrating screens offer a number of unique advantages that make them a firstline option What Is A Vibrating Screen? HUATAO GROUPWith over 400 sets of largescale vibrating screens being shipped to customers every year, AURY has become a major provider of vibrating screen to the mining industry in the world Full line of vibrating screens Vibrating Screens AURY AustraliaSingle Deck Screens, Twin Deck Screens, Triple / MultiDeck Screen; Multi Angle Screens, Banana Screens, Quarry Screens, Coal Screens, Potash Screens, Wash Screens, Wet Screening Bespoke Vibrating Screen Horizontal Screen by Don Valley Engineering

.jpg)

appm 1822 limestone crusher material combination

single deck vibrating screen coal washery wiki Basalt Crusher we can divide stone crushers into marble crusher, quartz crusher, limestone it's feeding style incoporates material single impact crusher l t size appm 1822; new innovation in crushing and screening CGM crusher quarry2024年9月18日 — Simply dumping washery rejects on vacant land adjacent to a coal washery is fraught with many problems (Pal et al2012),such as: Creates unsightly waste coal piles that occupy land that could otherwise be put to more useful purposes;coal washery equipments supplierCoal washery suppliers in India,for en/163/coal washery grindingmd at main lbsid/en GitHubEstablished in the year 2019, we “John Finlay India Private Limited” are a prominent firm that is engaged in Importer and Manufacturer a wide range of Vibration Screen, Magnetic Separator, etc Located in Ahmedabad (Gujarat, India), we are a PvtLimited Company firm and manufacture the offered products as per the set industry norms Our valued clients Importer of Motorized Vibrating Screen Dry Coal Washery 2019年8月12日 — The circular mode of vibration provided to the screen deck will incorporate the inertial force on the particle in the screen deck, reducing screen clogging The present study involves the analysis of the screening performance of the new vibrating screen with the coal feed of varying moisture content of 4%, 6% and 8%Evaluation of a new vibrating screen for dry screening fine coal

.jpg)

Vibrating Screen Single Deck Vibrating Screen rollcon

Condition:New Size:30 x 60 x 120Inch; Type:Other, Deck Vibrating Screen Capacity:15500 Ton/day Material:Stainless Steel Shape:Other, Rectangle Width:1200 Millimeter (mm) Voltage:220660 Volt (v) Supply Ability:10 Per Month Delivery Time:30 Days2023年8月2日 — The number of screen decks, motor power, wires, and springs may vary depending on the type and the size of the stone and mineral materials to be screened, and the desired capacity Vibrating screen is widely used in mining metallurgy, coal, building materials, chemical industry, cement, glass, grain, medicine and other industries due to Basic concepts of vibrating screens: What they are, what they