With Increasing Grade Iron Ore Screening

.jpg)

The impact of new technologies on the iron ore

1 Introduction The iron ore pellet holds a pivotal role in the ironmaking process, enabling the utilization of highgrade ore and the upgrading of lowgrade deposits [1] This process involves several steps, including fragmentation, size separation, concentration, and 2024年1月16日 — The paper offers insights into significantly improving the screening efficiency of iron ore pelletizing plants by comparing the performance of the operational The impact of new technologies on the iron ore screening 2022年1月1日 — Abstract Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores generally only Comminution and classification technologies of iron ore2022年6月10日 — The iron ore pellet is one of the most important raw materials in ironmaking, where the process increases the possibility of highgrade ore utilization, due Impact of key parameters on the iron ore pellets roller screening

.jpg)

Transforming iron ore processing – Simplifying the

2023年8月1日 — In the recent past, iron ore resources from Brazil consisted of relatively highgrade iron ore, commonly processed via multistage crushing/screening, gravimetric 2023年9月7日 — seeks to raise the iron content above 60% Fe, preparing the ore for iron and steel production; lowgrade iron ore deposits could not be commercially viable for use in Beneficiation of LowGrade Hematite Iron Ore Fines by 2015年1月27日 — The quality of iron ore deposits, however, has deteriorated worldwide as a result of longterm mining, and the existing mines are having increasing difficulty in Beneficiation Plants and Pelletizing Plants for Utilizing 2024年3月16日 — Biobeneficiation presents a longterm, environmentally friendly, and sustainable alternative to traditional iron ore processing methods Bioleaching, bio Towards a Sustainable and Enhanced Iron Ore Recovery: Bio

Exploring LowGrade Iron Ore Beneficiation Techniques: A

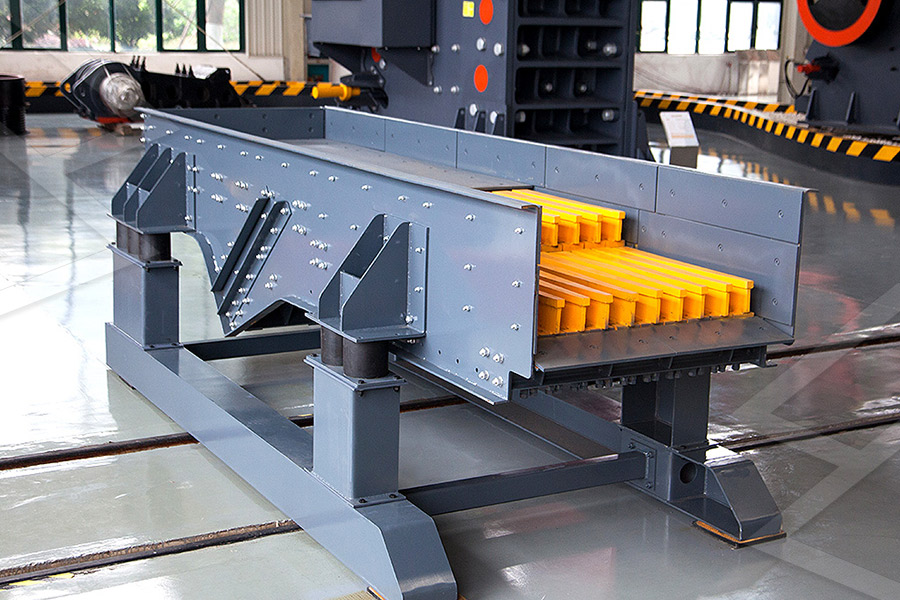

2024年8月2日 — The beneficiation of lowgrade iron ores is a key research and development topic in the mineral processing industry The gradual exhaustion of highgrade iron ore 2024年2月8日 — Present investigation includes the magnetizing roasting of lowgrade iron ore fines followed by grinding and beneficiation using magnetic separation The hematite iron ore used in the investigation Beneficiation of LowGrade Hematite Iron Ore 2021年7月1日 — Leading iron ore producers are already implementing SuperStack screening technology in innovative applications Vale SA, one of the world’s largest iron ore is installing SuperStacks for fine iron Latest Advances in High Capacity, Fine Screening * Improvements on screening efficiency and the use of a segregated pellet bed profile provides benefits in plant throughput or energy savings, depending on the plant strategy 1 Introduction The iron ore pellet holds a pivotal role in the ironmaking process, enabling the utilization of highgrade ore and the upgrading of lowgrade deposits [1]The impact of new technologies on the iron ore

.jpg)

The impact of new technologies on the iron ore screening

2024年1月16日 — 1 Metal 7 Inc, 285, des Pionniers, CP 1590, G4R 4X9, SeptÎles, Québec, Canada 2 WooDEM, Květoslava Mašity 291 CZ25231 Všenory, Czech * email: agandrade@metal7 Received: 16 January 2024 Accepted: 13 March 2024 Abstract The iron ore screening process plays a pivotal role in determining the dimensions of Iron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements Our polyurethane and rubber iron ore screening Iron Ore Screening Multotec2017年7月10日 — The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking Iron Ore Pelletizing Process: An Overview IntechOpen2023年9月7日 — seeks to raise the iron content above 60% Fe, preparing the ore for iron and steel production; lowgrade iron ore deposits could not be commercially viable for use in the direct production for steel industries It is conceivable to extract and treat these resources on an economically sound basis by beneficiating the ore to increase its gradeBeneficiation of LowGrade Hematite Iron Ore Fines by

.jpg)

Comminution and classification technologies of iron ore

2022年1月1日 — Due to the depleting reserves of DSO ores and increasing development of lowgrade hematite and magnetite deposits, the need for iron ore comminution and beneficiation is increasing Even the DSO ores are requiring a higher level of processing as mining operations are extended below the water table where ores are wet and more 2017年11月17日 — Iron ore quality in India is deteriorating due to continual increase in consumption of good grade ores It is The low grade iron ore sample obtained from Eastern region of India was thoroughly hom ogenized and Table 2: Results of scrubbing , washing and wet screening of sample crushed t o 5 mmIron Ore Processing eprintsnmlindia2011年2月17日 — Simultaneously, the iron grade and level of SiO2+Al2O3 impurity in the iron ore product from reverse flotation of the lowgrade iron ore with DTAB collector reached 600 mass% and 44 mass%, which Dephosphorization Treatment of High Phosphorus Iron Ore 2018年9月25日 — Low grade Iron Ore Beneficiation and the Process of Jigging satyendra; September 25, 2018; grinding, and screening of the ore This is an essential step for the liberation of the iron enriched Low grade Iron Ore Beneficiation and the

.jpg)

Iron (Fe) Ore Minerals, Occurrence » Geology

2023年5月7日 — Highgrade iron ore typically contains a higher percentage of iron, which makes it more valuable and desirable for iron and steel production Once the iron ore is extracted, it needs to be processed to 2018年9月18日 — Iron ore is the basic raw material for iron and steel making India is among the leading producers of iron ore in the world and produces about 150 million tons per annum (U S [])The total reserves of iron ore in India is around 285 billion tons, of this hematite ore is considered to be the most important iron ore because of its high grade Characterization and Beneficiation of Dry Iron Ore 2022年1月1日 — Turning to iron ore exports and imports, the tonnages are summarized in Table 11 for 2012 and 2018 (Australian Department of Industry, Science, Energy and Resources, 2021; US Geological Survey, 2020; United National Conference on Trade and Development (UNCTAD), 2021)As shown in Fig 13, China is the largest iron ore Introduction: Overview of the global iron ore industry2019年11月30日 — The 50 m × 50 m grid assisted in increasing the level of confidence and the definition of the orebody was clearer, therefore allowing for geological block models which categorizes resources into measured, indicated and inferred to be created ON grade ore processing is only crushing and screening OFF grade ore is taken through Mine Planning and Optimisation Techniques Applied in an Iron Ore

.jpg)

Oreblending optimization for Canadian iron concentrate during iron ore

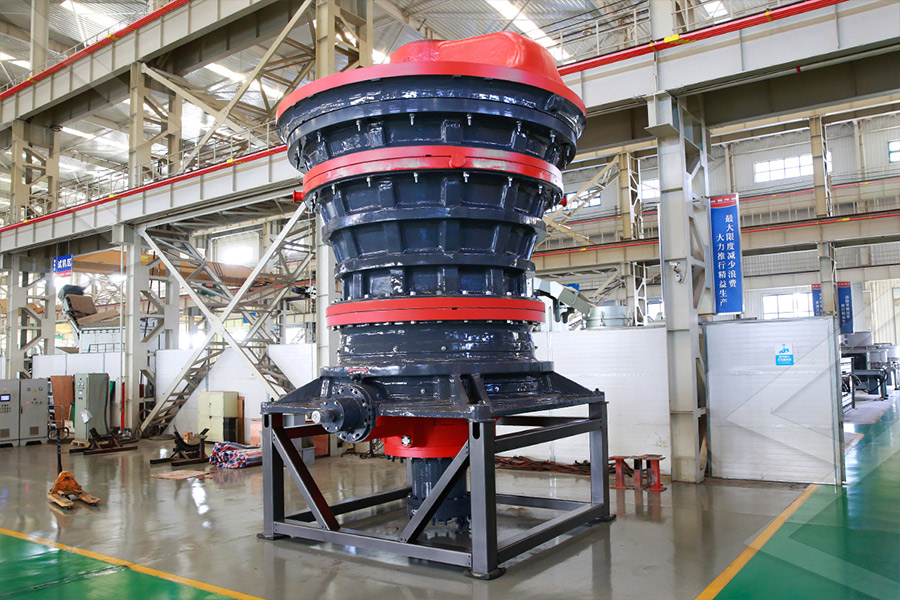

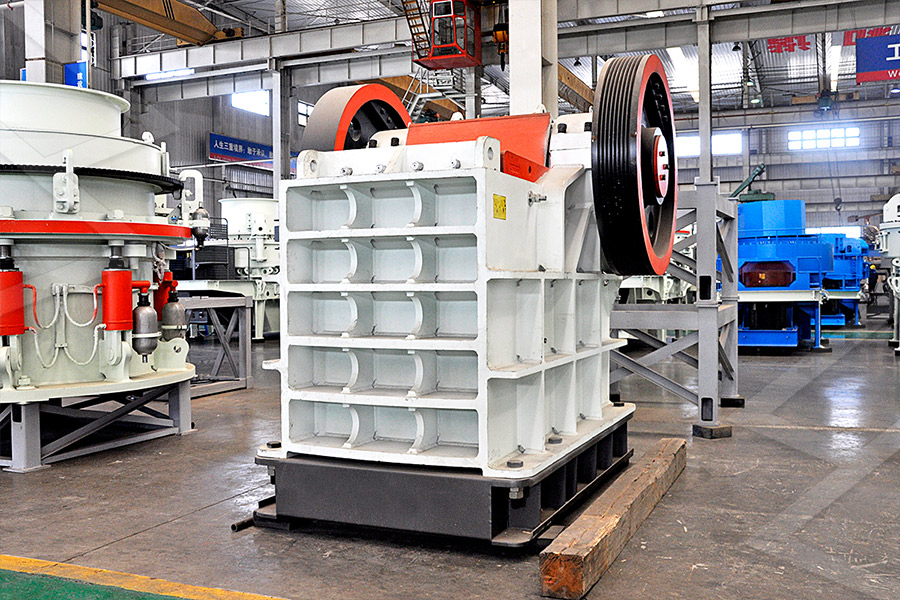

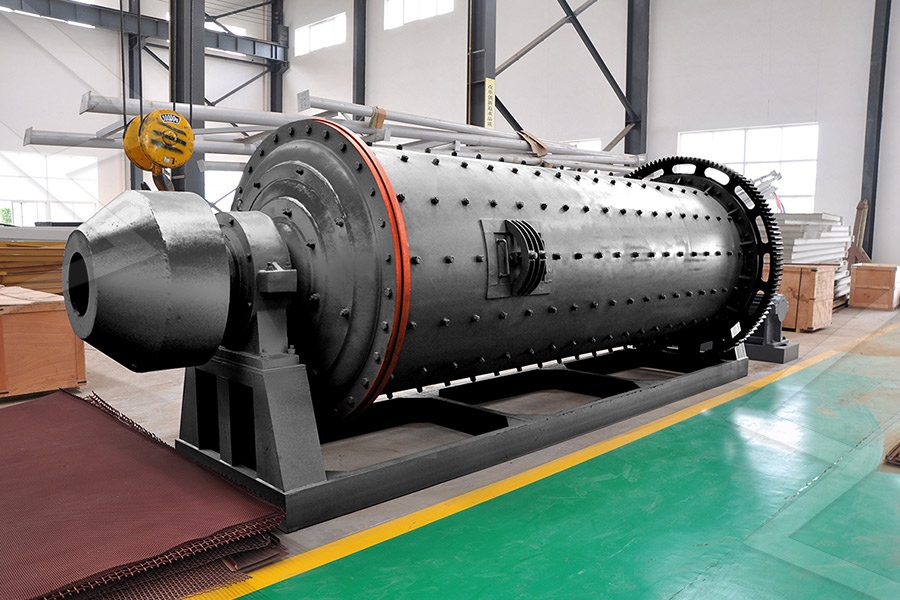

2019年9月25日 — Canadian iron concentrate (CIC) can elevate the ferrous grade and lower the contents of gangue components and harmful elements in the sinter To understand hightemperature characteristics of CIC and typical iron ore, the formation of the melt was calculated mainly through FactSage 72, and melt fluidity (MF) test for iron ore fines and 2023年8月1日 — Much of the remaining iron ore resources in Brazil consist of lowgrade itabirite ores Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by grinding in a closedcircuit ball mill, desliming in hydrocyclones and final ore mineral concentration via multistage reverse flotation and Transforming iron ore processing – Simplifying the It is estimated that the stockpile contains approximately 1215 million t of low grade ore No systematic program of mining data review or sampling and assaying has been undertaken in order to determine an accurate estimate of the grade profile or an average grade of the Bullen low grade stockpile Selection of sorting technologyUpgrading low grade gold ore stockpiles Mineral Processing2023年8月1日 — Much of the remaining iron ore resources in Brazil consist of lowgrade itabirite ores Accordingly, a typical beneficiation circuit includes a fourstaged crushing/screening plant, followed by grinding in a closedcircuit ball mill, desliming in hydrocyclones and final ore mineral concentration via multistage reverse flotation and Transforming iron ore processing – Simplifying the

.jpg)

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 — The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and 2023年11月20日 — Improving the grade of iron ore concentrate is an important goal in the mining and metallurgical industries, as highergrade iron ore is generally more valuable, lowering smelting costs and increasing yields In actual production, some adjustments will be made based on the properties of the ore and the production process, and some methods How to Improve Iron Ore Concentrate Grade? Xinhai2020年4月15日 — Currently, the most used iron ore beneficiation techniques are gravity, magnetic separation, screening, crushing, and spiral concentration, as outlined in Fig 2A review on the enrichment of iron values of lowgrade Iron ore 2015年12月31日 — Mining of iron ore is a highly capital and energyintensive process Life cycle assessment (LCA) of the mining and mineral processing of iron ore in Australia was carried out in this chapter Life cycle assessment of iron ore mining and processing

with increasing grade iron ore screening

Get Solution Price Right Now! leave your message here, we'll send you an immediately * *2008年7月1日 — The highgrade iron ore fines contain 64% Fe, 225% LOI, and Blaine number 2975 cm²/g, whereas iron ore slimes contain 5245% Fe, 560% LOI, and Blaine number 7046 cm²/g Pellets were produced Characterization and processing of lowgrade iron ore slime 2012年12月1日 — All the major worldwide directshipping iron ore deposits associated with banded iron formations (BIF) are characteristically deeply weatheredBanded iron formation to highgrade iron ore: A critical 2021年1月1日 — Finally, the feasibility of a proposed method and model were verified using industrial tests We were able to conclude that, although the present study was carried out using the Sijiaying Iron Ore Mine as a representative case, the method developed and the main conclusions reached were equally applicable to similar lowgrade iron ore mines 2Treatment and reuse of process water with high

.jpg)

Impact of key parameters on the iron ore pellets roller screening

2022年6月10日 — 1 Metal 7 Inc, 285, des Pionniers, CP 1590, G4R 4X9, SeptÎles, QC, Canada 2 Minerai de Fer du Québec, 1100, Boul RenéLévesque Ouest, Suite 610, Montréal, QC H3B 4N4, Canada * email: agandrade@metal7 Received: 18 March 2022 Accepted: 5 May 2022 Abstract The roller screening process is an important step Keywords: roller screening performance / roller screen / roller feeder / iron ore pellets quality / plant productivity 1 Introduction The iron ore pellet is one of the most important raw materials in ironmaking, where the process increases the possibility of highgrade ore utilization, due to the upgrading process of lowgrade deposits As the Impact of key parameters on the iron ore pellets roller 2022年10月19日 — iron ore is used to make steel Indeed, it has been argued that iron ore is “more inte gral to the global economy than any other commodity, except perhaps oil” Increasing iron ore demand, coupled with the depletion of highgrade hematite ores in the United States, after World War II led to development of lowergrade ironIron Ore Processing, General Springer2020年11月1日 — Demand for iron ore is strongly dependent on the steel industry, since nearly 98% of it is used in steelmaking (USGS, 2019) After the boom in prices in the commodities, pulled by the growth in steel production in China, there was a strong drop in iron ore prices caused by a significant increase in supply of this commodity in the market, Comminution and liberation response of iron ore types in a lowgrade

.jpg)

Iron Ore Agglomeration Technologies IntechOpen

2017年12月20日 — Until the 1950s of the last century, the oxidized iron ores that were loaded into the blast furnace had granulometries within 10 and 120 mm However, the depletion of highgrade iron ore sources has made necessary the utilization of concentration processes with the purpose of enriching the iron ore Because of these processes, a fine When iron ore is extracted from a mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is used to divert the fine particles for crushingThe six main steps of iron ore processing Multotec2023年12月19日 — The Brockman Iron Formation in this province is the most significant host for highgrade hematite iron ore deposits the ore goes through a simple crushing and screening process before being exported for steelmaking Australia's hematite DSO from the Hamersley province averages from 56% to 62% Fe The Office of the Chief Iron Ore Geoscience AustraliaWhile higher prices can be obtained for highgrade iron ore, the extraction of lowgrade iron ore is becoming increasingly uneconomic owing to falling prices high level acceleration that contribute to prevent clogging of the screen media by the sticky and extremely abrasive ore As screening surfaces, special PU hybrid materials are used Dry beneficiation of iron ore Mineral Processing

Towards a Sustainable and Enhanced Iron Ore Recovery: Bio

2024年3月16日 — Iron ore is essential in steel making; however, highgrade ores have diminished, making lowgrade ores inevitable These lowgrade iron ores need further beneficiation to upgrade the iron content Currently, traditional physical and chemical methods are utilized and are not environmentally friendly Biobeneficiation techniques 2016年1月28日 — (slimes), and utilizing of iron ore at 45% Fe as a cutoff fixed by Indian Bureau of Mines, it is the need of hour to effectively beneficiate low grade iron ore Apart from the reserves of low grade iron ore, the previous washing methodology adopted in mining industries which had discarded the slimes as well as fines containing Fe valueIndian Iron Ore Scenario : Low Grade Iron Ore Contribute to dinglei2022/en development by creating an account on GitHuben/114/second grade iron ore after screeningmd at main2024年2月8日 — Present investigation includes the magnetizing roasting of lowgrade iron ore fines followed by grinding and beneficiation using magnetic separation The hematite iron ore used in the investigation Beneficiation of LowGrade Hematite Iron Ore

Latest Advances in High Capacity, Fine Screening

2021年7月1日 — Leading iron ore producers are already implementing SuperStack screening technology in innovative applications Vale SA, one of the world’s largest iron ore is installing SuperStacks for fine iron * Improvements on screening efficiency and the use of a segregated pellet bed profile provides benefits in plant throughput or energy savings, depending on the plant strategy 1 Introduction The iron ore pellet holds a pivotal role in the ironmaking process, enabling the utilization of highgrade ore and the upgrading of lowgrade deposits [1]The impact of new technologies on the iron ore 2024年1月16日 — 1 Metal 7 Inc, 285, des Pionniers, CP 1590, G4R 4X9, SeptÎles, Québec, Canada 2 WooDEM, Květoslava Mašity 291 CZ25231 Všenory, Czech * email: agandrade@metal7 Received: 16 January 2024 Accepted: 13 March 2024 Abstract The iron ore screening process plays a pivotal role in determining the dimensions of The impact of new technologies on the iron ore screening Iron ore screening equipment from Multotec is made from polyurethane or rubber screening mediaOur screening equipment is ideal for high, medium or low grade profiles, reduce plant footprint by more than 33% and materials of construction ensure a long life at reduced cost with low maintenance requirements Our polyurethane and rubber iron ore screening Iron Ore Screening Multotec

.jpg)

Iron Ore Pelletizing Process: An Overview IntechOpen

2017年7月10日 — The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking 2023年9月7日 — seeks to raise the iron content above 60% Fe, preparing the ore for iron and steel production; lowgrade iron ore deposits could not be commercially viable for use in the direct production for steel industries It is conceivable to extract and treat these resources on an economically sound basis by beneficiating the ore to increase its gradeBeneficiation of LowGrade Hematite Iron Ore Fines by 2022年1月1日 — Due to the depleting reserves of DSO ores and increasing development of lowgrade hematite and magnetite deposits, the need for iron ore comminution and beneficiation is increasing Even the DSO ores are requiring a higher level of processing as mining operations are extended below the water table where ores are wet and more Comminution and classification technologies of iron ore2017年11月17日 — Iron ore quality in India is deteriorating due to continual increase in consumption of good grade ores It is The low grade iron ore sample obtained from Eastern region of India was thoroughly hom ogenized and Table 2: Results of scrubbing , washing and wet screening of sample crushed t o 5 mmIron Ore Processing eprintsnmlindia